- Home

- Custom Box Inserts

Custom Box Inserts

GPPacking’s custom box inserts combine meticulous engineering with diverse materials like cardboard, foam, molded pulp, and plastic for optimal product protection.

Custom Size

Low Moq

360° design

Sustainable

Full-color printing

Get Started with GPPacking!

We always want to make sure our customers get the best price, so please let us know what you are interested in and we will provide a quote!

Custom E Box Inserts Inspiration

Our custom boxes are tailored for a variety of products and industries, from chic elegance to creative unboxing experiences, to elevate your brand with impressive packaging.

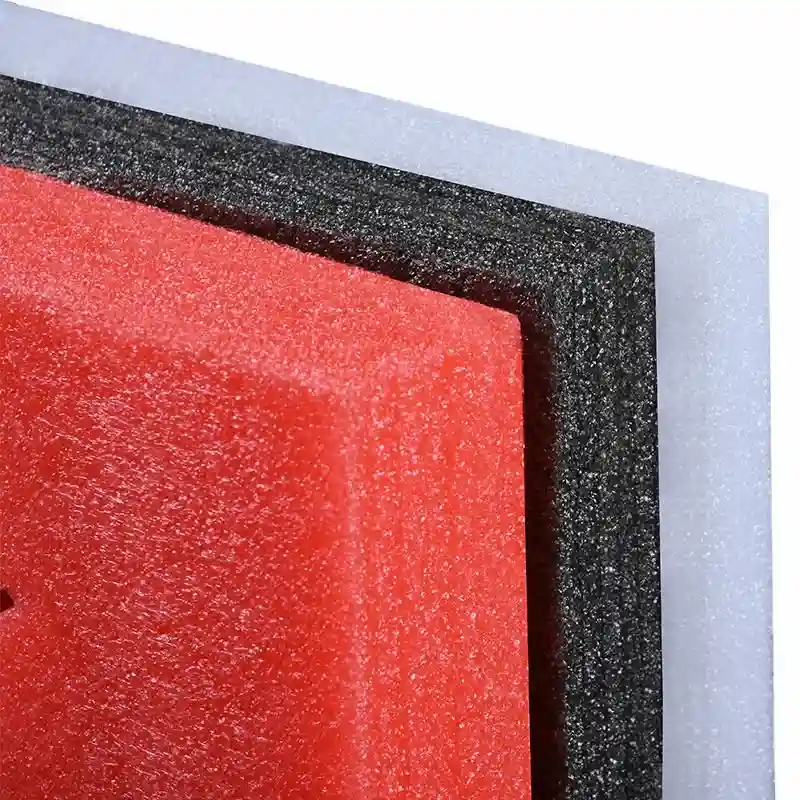

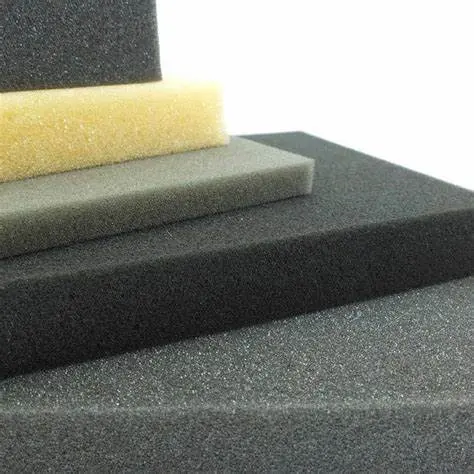

Foam Inserts

- 4-5 colors with CMYK + spot colors

- Photo quality printing with smooth gradients

- Effective for long, multi-page book printing

Cardboard Inserts

- 4-5 colors with CMYK + spot colors

- Photo quality printing with smooth gradients

- Effective for long, multi-page book printing

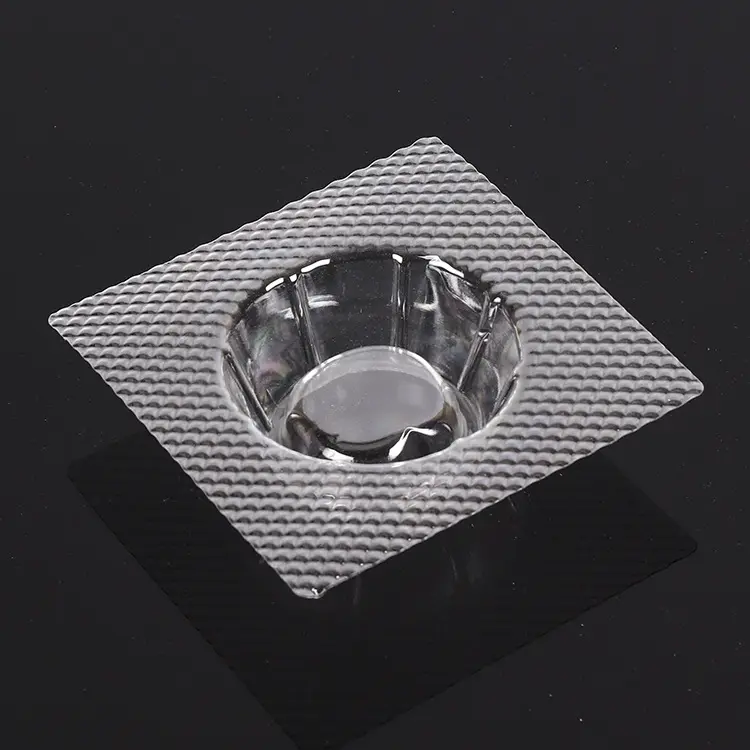

Plastic Tray Inserts

- 4-5 colors with CMYK + spot colors

- Photo quality printing with smooth gradients

- Effective for long, multi-page book printing

Molded Pulp Inserts

- 4-5 colors with CMYK + spot colors

- Photo quality printing with smooth gradients

- Effective for long, multi-page book printing

Custom foam box inserts

foam Packaging Inserts

From color and density to size and shape, we custom high-quality, logo-printed sponge inserts designed to securely cushion your unique items during shipping and storage.

- Superior Cushioning - Sponge foam absorbs impacts exceptionally well to prevent damage.

- Density Control - We can engineer precise densities to match product needs.

- Quick Recovery - Sponge instantly regains its shape after compression.

- Customizable - Can be cut to any size and shape and printed on.

- Eco-Friendly - Made of recyclable materials like polyurethane foam.

EPE

Lightweight and eco-friendly, cushioning protection, general resistance to pressure.

EVA

Soft and elastic, water resistant, suitable for waterproof packaging.

PU

High-density wear-resistant, strong pressure resistance, higher cost.

ESD

Anti-static, protect electronic equipment.

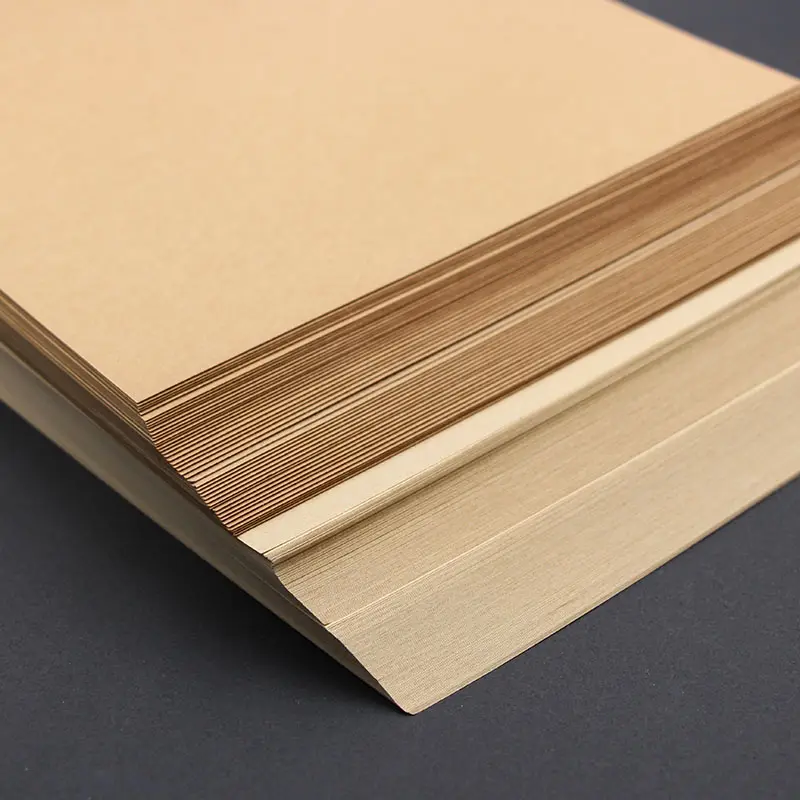

Custom Cardboard Inserts

Cardboard packaging Inserts

Our cardboard insert liners showcase and protect products with custom-shaped paperboard molded precisely to each item’s contours. As renewable materials, responsibly-sourced cardboards have environmental and regulatory advantages over plastics. Thickness and durability adapt based on box and product requirements.

- Custom Fit - Die-cut to precisely fit packaging dimensions.

- Strength - Sturdy multi-layered cardboard construction.

- Sustainability - Renewable, recyclable and biodegradable.

- Streamlined Usage - Fits products for faster packaging.

- Configuration Options - Numerous printable colors, faces, cutouts and structures.

C1S

Coated side, smooth and wear-resistant, suitable for high-grade packaging.

Natural Kraft

Natural fiber, high strength, environmental protection and durability.

Kraft Board

Structural support, lightweight, cost effective.

White Board

Smooth on both sides, good color performance, commonly used in gift boxes

Custom plastic and blister inserts

plastic and blister packaging Inserts

Our plastic blister liners showcase and protect products with custom-molded PET or PVC shaped precisely to each item. Economic pricing makes large volumes extremely cost-effective globally. Thickness adapts based on box and product specs.

- Enhanced Visibility - Crystal clear optical grades of PET/PVC help items stand out, while preventing obscuring scratches or cracks.

- Tamper Evidence - Once sealed, plastics clearly show if opened, vital for pharmaceuticals, electronics and food.

- Customized Fit - Precision modeling and thermoforming ensures every unique shape or component has a perfect custom plastic cocoon.

- Supply Chain Economy - Durability for repeated usage and recycling lowers lifecycle costs far below paper-based inserts.

- High Speed Integration - Blisters are formed through a highly automated process that allows for easy mass production.

PET

Transparent and tough, heat resistant.

PVC

Soft and moldable, chemical resistant.

PP

Lightweight and heat resistant, resistant to bending.

HDPE

Tough and durable, water resistant.

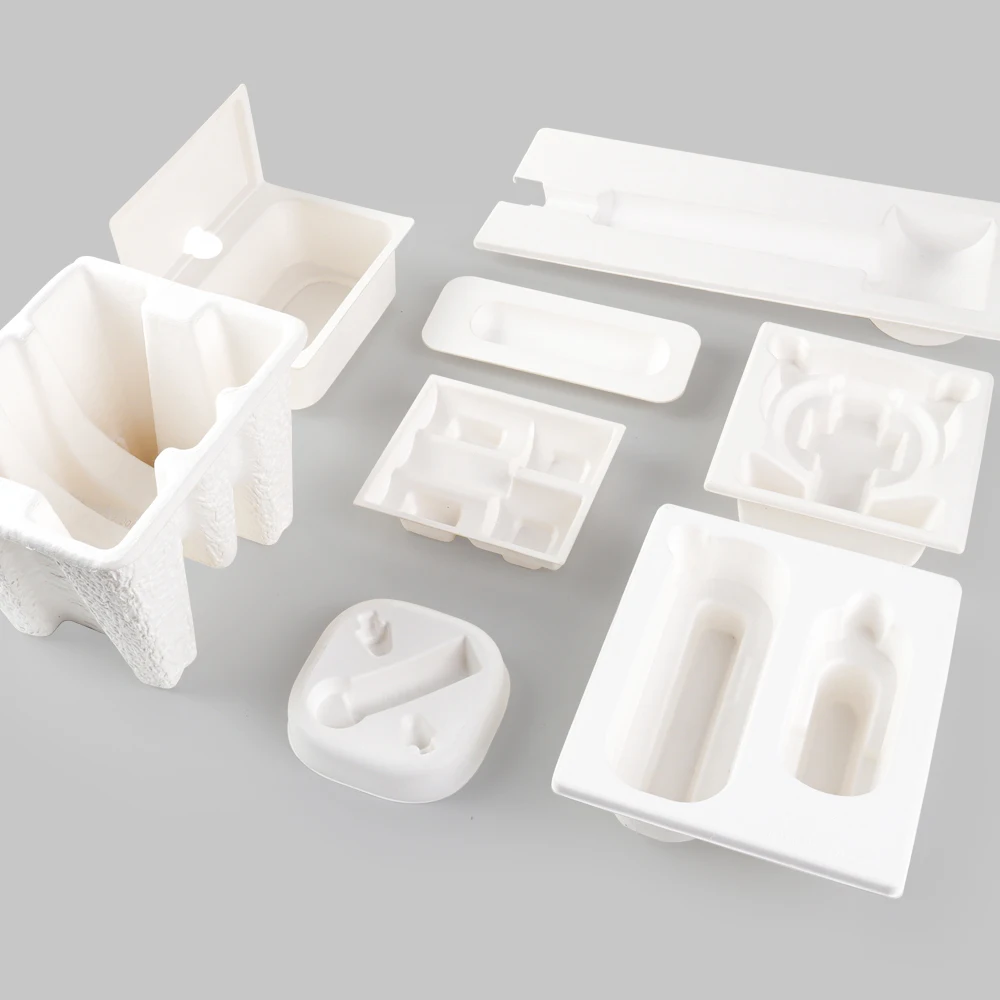

Custom Molded pulp inserts

Molded pulp Packaging inserts

Our molded pulp insert liners showcase and protect products with custom-shaped forms made from recycled paper pulp molded precisely to each item’s contours. As highly sustainable materials, molded pulp has significant environmental advantages over plastics.

- Eco-Friendly - Made from 100% recycled paper pulp, molded pulp is completely biodegradable and compostable.

- Lightweight - Ultra low density results in 60% lighter packaging over plastic, saving heavily on transport.

- Protective Properties - Engineered pulp fiber matrices absorb impacts and distribute force to secure items.

- Rapid Prototyping - Adjustable digital files enable fast revisions or short test production runs to optimize inserts.

- End-of-Life Options - Can dissolve in water when no longer needed or break down entirely in industrial composters.

Dry Press

Fast molding, lower cost, suitable for mass production.

Wet Press

Fine molding, high plasticity, suitable for complex shapes.

Can’t Find Ideal Custom Packaging For Your Industries?

We provide custom solutions to all our customers and offer free pakcing samples that you can take advantage of.

How to customize the inserts to fit your product

We can ensure that you have the most appropriate lining solution for your product that will both protect it and enhance the customer experience.

Product analysis:

First of all, we will conduct a comprehensive analysis of your product, including size, weight, shape, fragility and whether anti-static or moisture-proof treatment is required.

Material Recommendation

Depending on the characteristics of the product, we will recommend the most appropriate material. For example, foam or pearl cotton may be recommended for fragile products, and bubble wrap may be chosen for products that need to be shockproof.

Size Measurement

We will accurately measure the size of the product and design the size of the liner according to the shape of the product to ensure that the liner fits tightly and reduces shaking during transportation.

Customized design

We will work with you to design the internal structure of the liner, such as grooves, dividers, etc., to ensure that the product is placed stably in the insert.

Sample making

We will make samples of the inner liner, and you can conduct actual tests to verify the protective effect of the liner and the adaptability of the product.

Feedback Adjustment

Based on the feedback from the sample test, we will make necessary adjustments to optimize the liner design.

Mass Production

Once the samples are approved, we will move into mass production to ensure that each batch of liners meets your quality standards.

Quality Control

Throughout the production process, we implement strict quality control measures to ensure that each product achieves the desired protective effect

CustomEco-Friendly Packaging for your products

At GPPacking, we are proud to offer a wide selection of over 500 in-stock wholesale mailing box designs and styles, all of which can be found in our fully equipped warehouse. Our diverse range of mailing boxes meets the needs of many industries including retail, beauty, food, beverage and electronics.

Custom Box Inserts That Fit Your Brand

Custom box inserts based on your preferred size and design. A wide range of internal box sizes and materials are available.

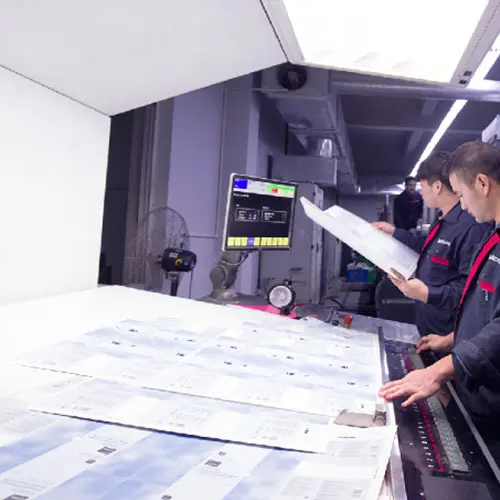

Trusted Chinese Box Inserts Supplier

Our technical and industrial teams offer a wealth of expertise to support you in defining your printed packaging projects and ensure perfect compatibility between our packaging and your products and brands, thus guaranteeing our mutual success.

- 20 years of experience creating innovative, sustainable packaging for 500+ brands globally.

- 10+ skilled designers on staff using latest 3D modeling and rendering technology.

- 30 enterprise-grade printing and decorating machines, including 18 digital inkjet and flexographic printers.

- Proven track record with 95% on-time delivery rate thanks to streamlined logistics.

- Onsite quality control lab and testing at every stage of the production process.

- Strategic partnerships with raw material suppliers to mitigate supply chain risks.

- Flexible production process, support for small batch customization, to meet personalized needs.

- With eco-friendly materials, our designs align with environmental values.

what makes us different

Premium service you won't experience with other providers

Speed

Our fully automated production floor enables us to deliver initial packaging prototypes in 5 days as well as reduce average production cycles by 8 days compared to the industry standard.

Quality

In addition to a <1% defect rate, we employ microsensor scanning to ensure each dimension adheres within 0.2mm of specifications.

Range

We offer over 50 customizable box materials from sustainably-sourced paperboard to luxe metals and acrylics, along with more than 100 customizable finishes and production capabilities.

Sustainable Solutions

Our product range incorporates the latest innovations such as recycled inks, renewable grommets and fully compostable materials. We offer extensive consulting to help our customers achieve their ecological goals.

Innovation

We continually re-invest 12% of profits into R&D, having pioneered enhancements this year alone like antimicrobial coatings, user-replaceable plastic films, and paper-foam composites.

Cost Savings

Box customization through our end-to-end capabilities provides efficiency benefits reflected in savings of 15-30% for 70% of customers compared to alternatives.

FAQ Of Custom Box Inserts

Do you have questions about custom Corrugated Boxes? We have a list of frequently asked questions below. If you have more inquiries beyond what you can find here, our customer support is ready to answer them, 24/7.

What kind of inserts can you provide?

We offer a wide range of protective liners, such as foam, pearl cotton and EVA materials, which have good cushioning properties and can effectively absorb shocks during transportation to protect your fragile products.

Can you customize fully-fitted inserts?

We use precise measurements and customized designs to ensure that the liners not only fit the shape of the product perfectly, but also provide stable support to prevent the product from moving inside the package.

Can I have my brand logo printed on the inserts?

Yes, we can print your brand logo, product information or any design you wish to display on the inner liner to enhance your brand image.

Do you offer inserts in environmentally friendly materials?

We offer a range of eco-friendly materials such as recyclable cardboard and biodegradable foam that protect the product while meeting sustainability requirements.

What is the usual lead time for customized inserts?

Delivery times are dependent on the complexity of the order and production scheduling, we will provide an exact delivery date upon confirmation of the order and will endeavor to meet your timing requirements.

How is the cost of a customized insert calculated?

The cost will be determined based on the material selected, the complexity of the design, the quantity of customization, and whether special treatment (e.g. printing) is required, and we will provide a detailed quotation.

Do you provide sample testing service?

Yes, we offer free sample making to give you the opportunity to test the performance and quality of your inserts before mass production.

Can you provide anti-static inserts?

We offer inserts made of anti-static materials, such as anti-static foam and anti-static cardboard, which are effective in preventing static electricity from damaging sensitive electronic equipment.

Ask for a

quote today

We offer a one-stop packaging service, backed by packaging experts and more than 20 years of packaging industry research.