Custom Packaging Options

GPPacking’s comprehensive range of packaging materials, with customizable solutions to meet every need, offers a wide selection of papers, finishes and unique special features.

- Home

- Custom Packaging Options

Table of Contents

Material

PaperBoard

We offer a variety of paperboard options including different thicknesses, finishes (e.g. matte, glossy, laminated) and color choices to meet your packaging needs from lightweight to heavy-duty.

C1S

With a glossy coated surface, C1S offers vibrant printing, making it ideal for product packaging that demands a polished finish.

C2S

Paper coated on both sides, maximizing print quality, gloss and moisture resistance. Popular for high graphic packaging.

Natural Kraft Paper

Brown, unbleached paper made from wood pulp. Strong, breathable and low cost.

Woodfree Paper(W/F)

Made from chemically-pulped hardwood and softwood fibers. Smooth, brighter surface than uncoated papers.

Color Woodfree

Offers a variety of shades for creative packaging, adding pops of color to enhance product visibility and appeal.

CCNB

Clay Coated News Back – an economical paperboard with bright white clay coating for improved printing.

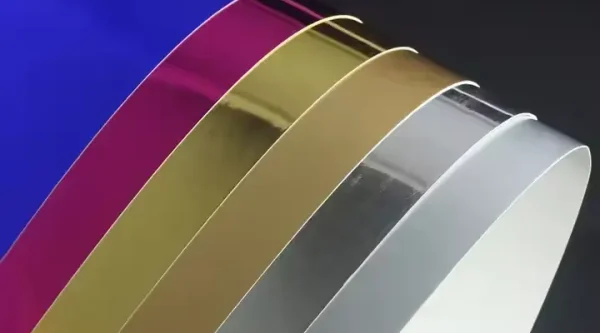

Metallic Paperboard

The surface has a metallic sheen and a unique texture. Ideal for luxury-feel packaging such as cosmetics and electronics packaging

Textured Paperboard

Surface with texture, good handfeel and rich visual effect. Commonly used in gift packaging and artwork protection.

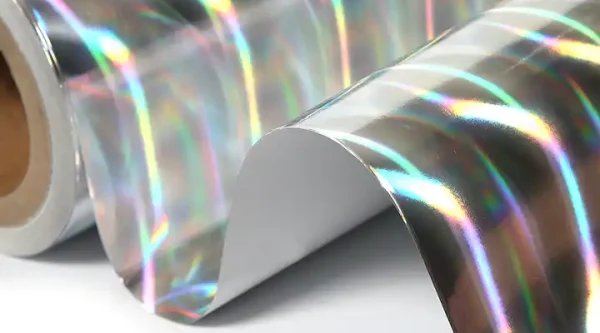

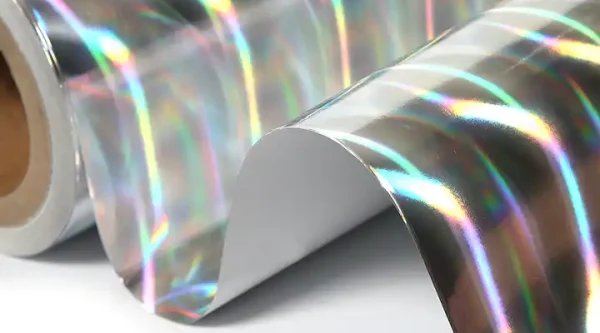

Holographic

Iridescent film laminate for decorative packaging with shifting rainbow effects. Provides security and anti-counterfeit.

White Kraft

High opacity, moisture resistant coated kraft with premium white shade for cosmetics and retail products.

Holographic

Iridescent film laminate for decorative packaging with shifting rainbow effects. Provides security and anti-counterfeit.

Coated Kraft (CCK)

Strong water-resistant kraft paper with a coating to improve print quality with good cost-performance balance.

RIgid Board

Our hardboard series covers a variety of materials, such as gray board paper and specialty paper, as well as rich surface decoration techniques. These hard board materials are strong and durable.

Grey chipBoard

A dense and sturdy board made from recycled paper fibers that has a gray surface and even grain. Suitable for rigid boxes and partitions requiring good stiffness and edge strength across a variety of industries.

White Board

White chipboard boasts a clean, bright appearance. Its smooth surface makes it perfect for high-quality printing, often chosen for premium product packaging, cosmetics, pharmaceuticals, and luxury items.

Solid black board

Has good compression and abrasion resistance, providing an upscale, elegant aesthetic to rigid boxes and displays. Most commonly used for high-end packaging of jewelry, spirits and specialty gift products.

Dyed Grey chipBoard

The gray cardboard is dyed and comes in a variety of colors, which can be customized according to brand needs. Suitable for personalized packaging, such as fashion products and electronic product packaging.

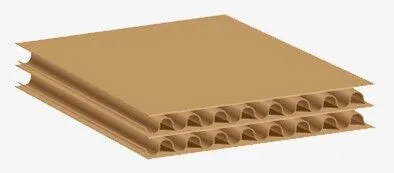

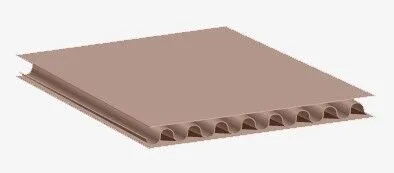

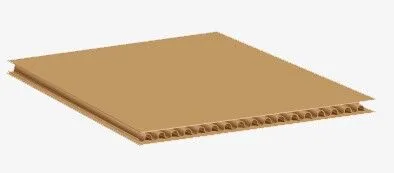

Corrugated Paper

We have a variety of corrugation types (such as Type A, Type B, Type C and Type E) and different cardboard combinations to suit different protection levels and load-bearing requirements.

Single Face

made of one layer of corrugated board and one layer of linerboard, simple structure, lower cost, suitable for lightweight packaging.

Single Wall

made of a single layer of corrugated board, lightweight and economical, suitable for inner packaging or light-weight items.

Double Wall

made of two layers of corrugated board and two layers of linerboard, provides extra strength and is suitable for medium-weight items.

Triple Wall

Three layers of corrugated board and top paper, strong structure, suitable for heavy weight items, providing better protection.

Common Appearance

Corrugated surface without special treatment, cost-effective and suitable for general commercial packaging.

WA Board

made of white face paper and corrugated board, with a whiter appearance, suitable for packaging that requires a certain level of aesthetics.

Double White Board

Both sides are made of white face paper with a neat appearance, suitable for packaging of high quality products.

A-Flute

Wide spacing between corrugations, provides good cushioning performance and is suitable for fragile items.

B-Flute

Moderately spaced corrugations provide both strength and cushioning, suitable for packaging a wide range of items.

C-Flute

Narrower flute spacing, sturdy structure, suitable for heavy items and products requiring extra protection.

E-Flute

Narrowest flute spacing, provides maximum strength and is suitable for heavy items and industrial packaging.

F-Flute

Widest spacing between corrugations, provides maximum cushioning, suitable for lightweight items but needing shock protection.

Printing & Inks

Print Methods

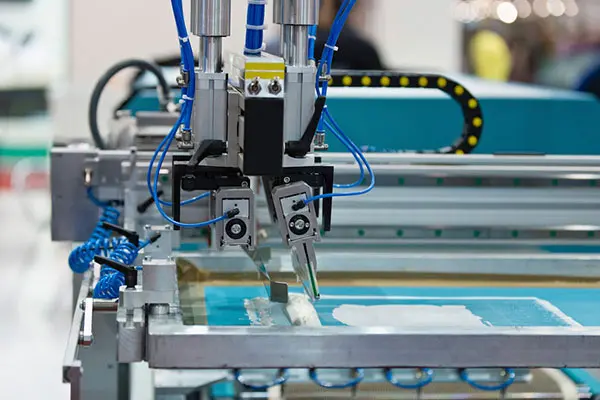

We provide a variety of printing technologies including offset printing, flexo printing, and screen printing to ensure fine printing effects and stable colors. We also support personalized customization to meet your high standards for packaging printing.

Offset Printing

Ink is transferred from the printing plate to the blanket and then to the printing surface, allowing for high quality printing in large quantities.

Screen Printing

The ink is applied to the surface of the box through a mesh screen. This method allows for detailed and colorful designs that are suitable for custom packaging.

Digital Printing

Printing designs directly onto packaging materials using electronic transmission. It offers flexibility, cost-effectiveness and customization for smaller print runs.

UV Printing

Uses UV light to cure the ink immediately producing vibrant colors, enhanced durability and a glossy finish.

Flexographic Printing

Transferring ink to various substrates, such as cardboard boxes, using flexible letterpress plates is a common and efficient way to print large quantities with versatility and high quality.

Gravure Printing

Printing with rubber plates has the advantages of light printing pressure, high printing quality, wide range of applications, etc., and can achieve bright colors and delicate images.

Lasers engraving

The laser makes small cuts and engravings on the packaging material, cutting through the surface of the box and generating a skeleton pattern to form beautiful graphics.

Inks

Our ink innovation uses nano-scale pigments and environmentally friendly formulas to achieve more vivid color performance and long-lasting gloss effects, while ensuring environmental protection and safety during the printing process.

Water-based Ink

An eco-friendly ink, with water as solvent, suitable for all kinds of printing, especially for food, medicine and other packaging printing with strict hygiene requirements.

Vegetable Ink

100% eco-friendly, soybean, flax and other plant-based inks are harmless to the environment and human health, and can be printed in vibrant colors.

Oil-based inks

Composed of oil and pigment, it produces bright colors and clear patterns. Its good adhesion and weather resistance maintains stable quality in various environments.

Fluorescent Color Ink

It can emit visible light under UV light irradiation, with bright and saturated colors to attract people’s attention. Meanwhile, it has certain anti-counterfeiting performance.

Pantone

Standard color card, can ensure the consistency of the color of the printed materials, improve the printing effect, make the product more attractive.

Finishes

We offer a variety of surface treatment options, including varnish, matte, foil stamping and spot UV, to meet your full range of packaging texture, gloss and personalized design needs.

Embossing

The surface shows raised patterns and textures with obvious relief three-dimensionality, which enhances the artistic infectivity of the printed matter

Debossing

The surface shows concave patterns and textures with obvious relief three-dimensionality, which enhances the artistic infectivity of the printed matter

spot UV

Curing localized UV coating in designated areas, matte or glossy, to enhance the three-dimensionality and artistic effect of the pattern.

UV Vanish

Curing the ink by UV irradiation makes the surface smooth and glossy. It enhances color, glossiness.

Gold & Silver Foil

Transfer different metal foils, such as gold, silver, etc. to the surface of the package by thermal transfer, forming a unique metallic luster.

Lamination

On the surface of the packaging coated with different materials of the protective film to make it more texture and aesthetics, and increase its moisture-proof, tear-proof and other properties.

Stencil

Translucent engraving processing background or let the hollowed out part become a pattern. It allows consumers to visualize the product and increase the attractiveness of the product.

laser

It can produce holographic patterns, rainbow luster unique visual effects on the box, with high resolution and accuracy, applicable to a variety of materials.

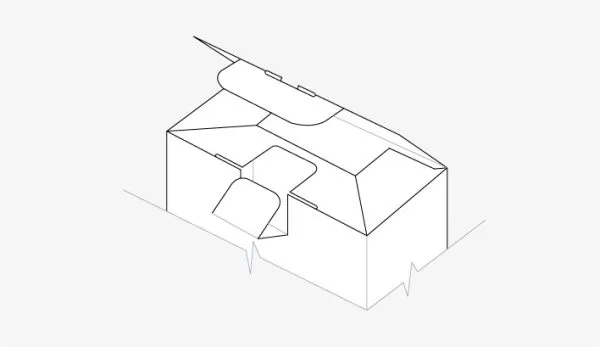

Inserts & Trays

We carefully design a variety of box lining materials, such as velvet, foam and pearl cotton, to ensure product safety and enhance the unboxing experience, while allowing for custom patterns and colors to add an extra touch of luxury and branding to product packaging.

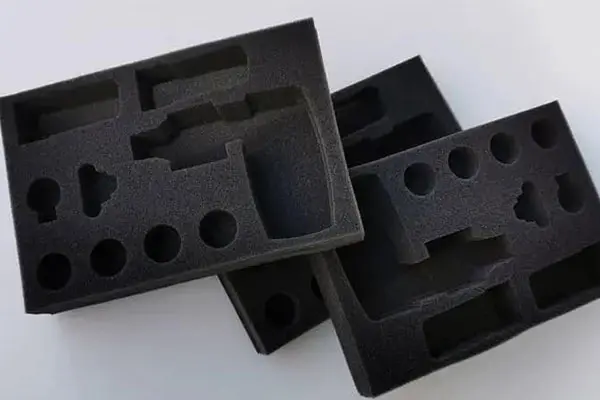

EVA insert

EVA inserts can be molded 1:1 according to the shape of the product. It has good elasticity, flexibility, anti-stamping, and can well protect the goods from damage by external factors.

Sponge & Pearl Cotton Insert

Sponge is a kind of porous material, rich in good ductility and elasticity, good protection of fragile goods. Pearl cotton is made of low-density polyethylene resin through physical foaming to produce countless independent air bubbles.

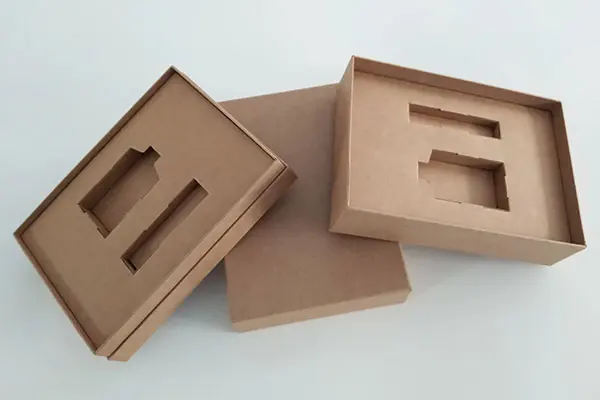

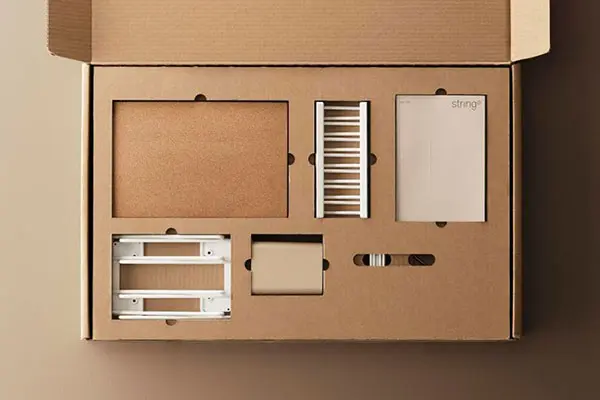

Cardboard insert

Cardboard inserts are eco-friendly, easy to load and unload, and can be die-cut into various shapes of grooves to hold products in place.

Blister & paper-molded insert

Blister inserts are made from 1:1 injection molding and are more stable and compression-resistant than other inserts. The paper-plastic inserts are the newest environmentally friendly inserts, made of paper and fiber pulp, and are most commonly used for cell phone inserts.

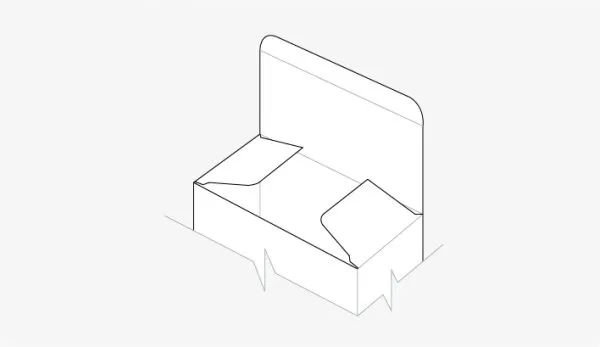

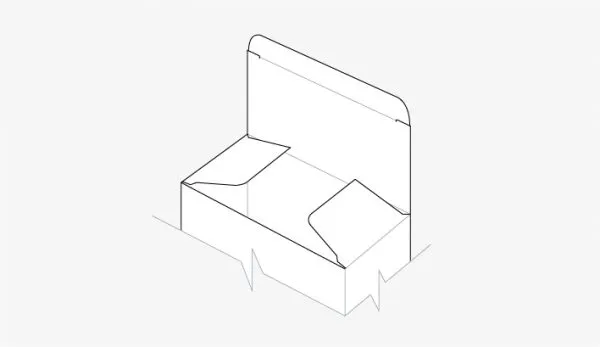

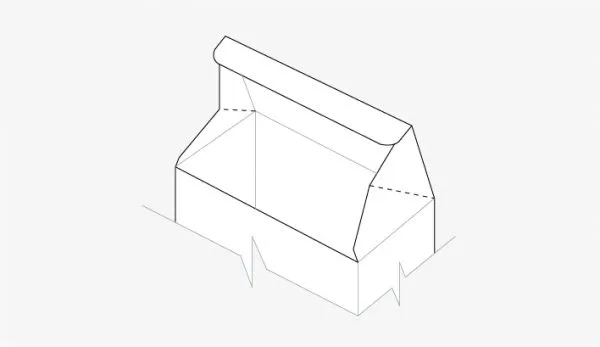

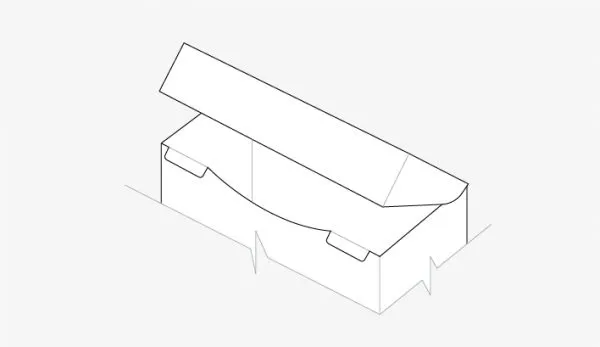

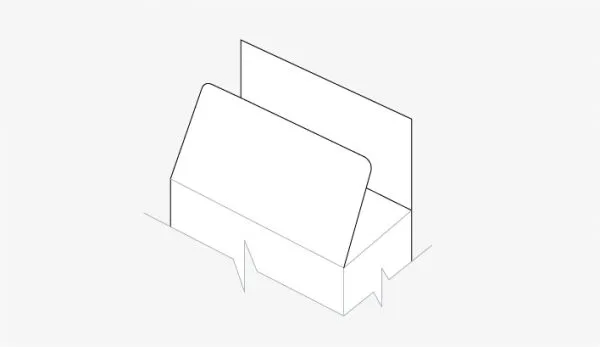

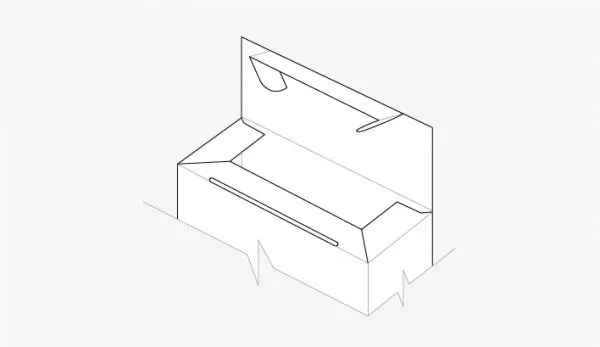

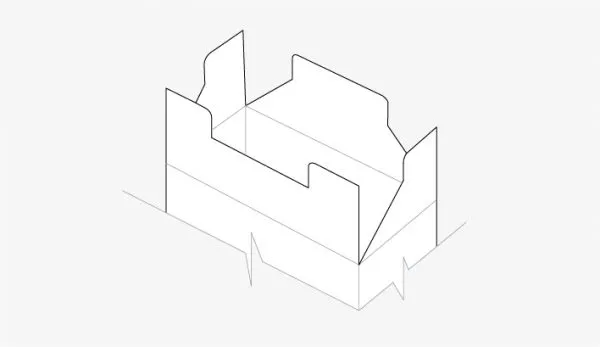

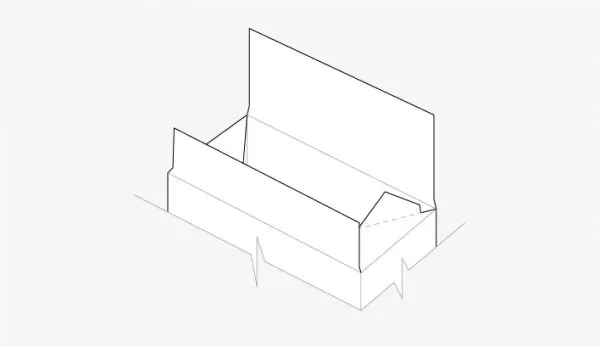

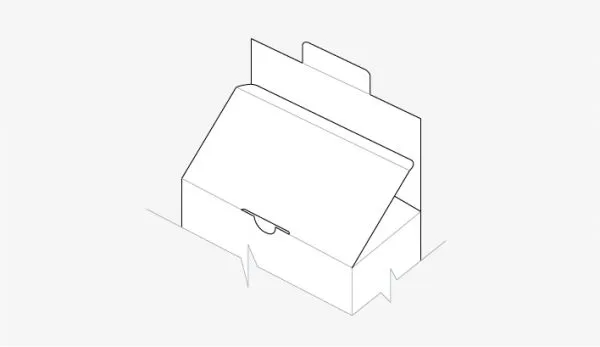

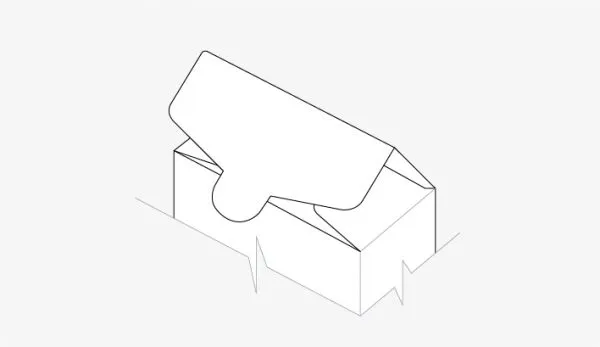

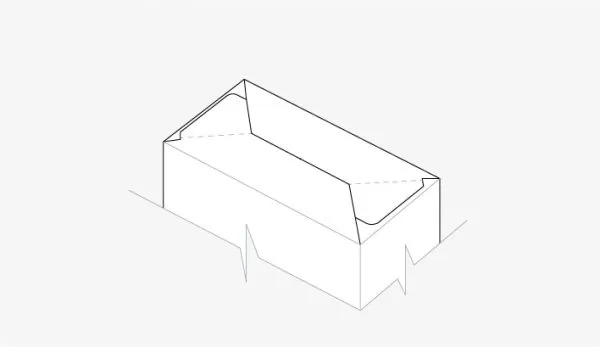

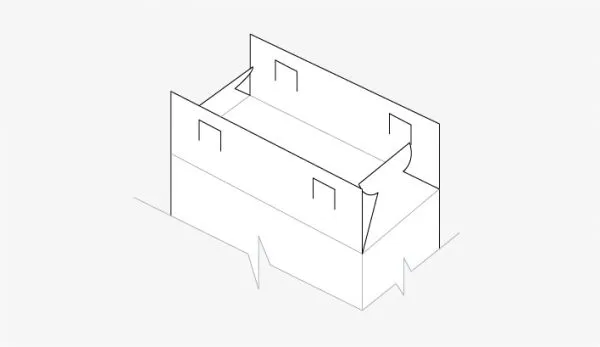

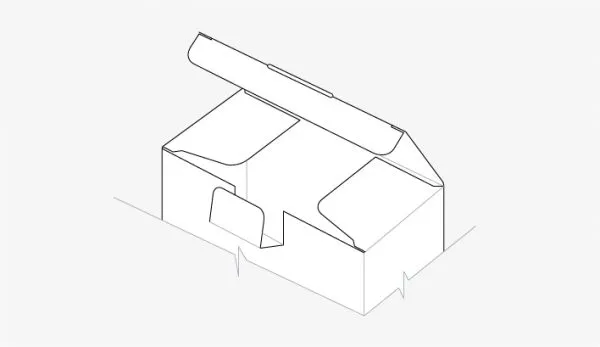

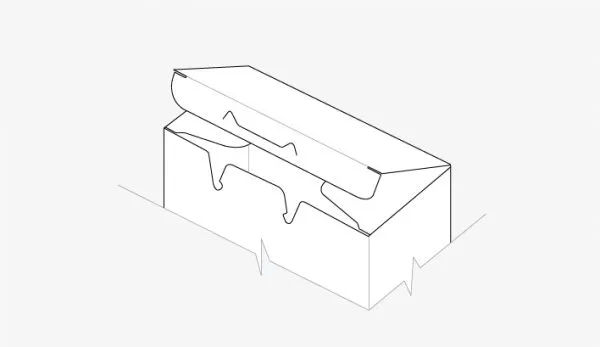

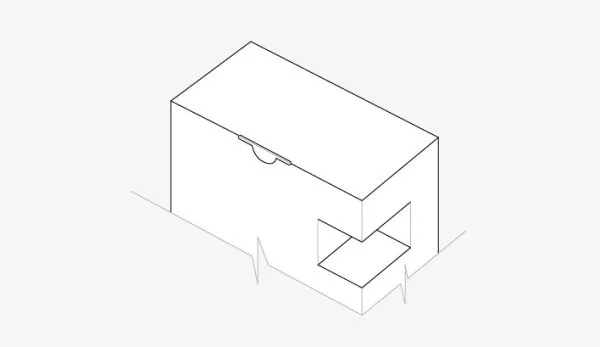

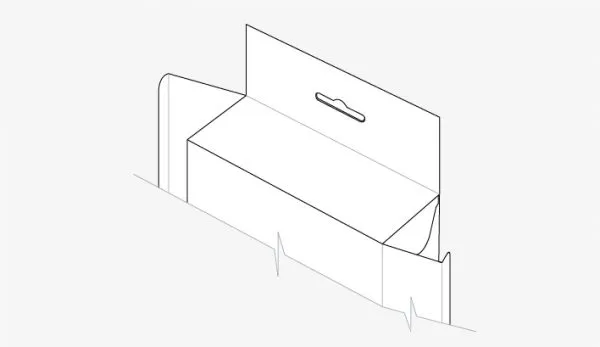

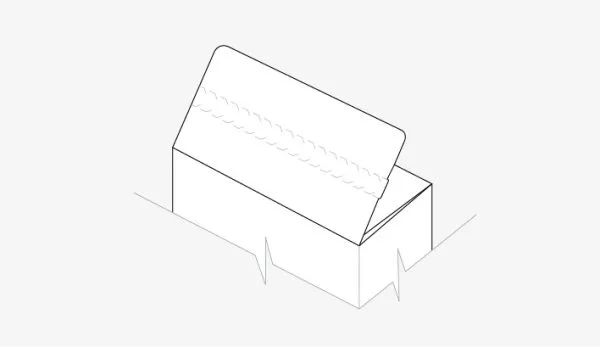

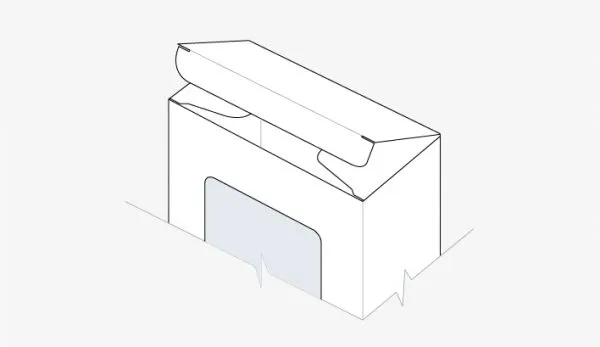

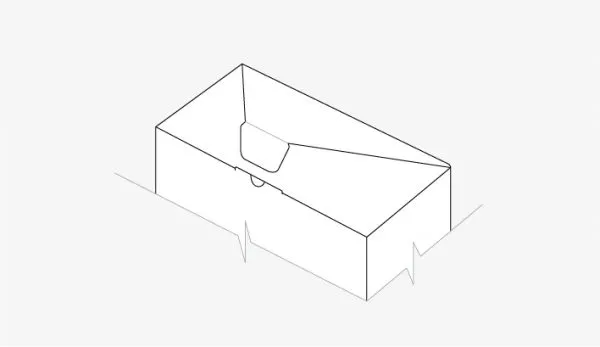

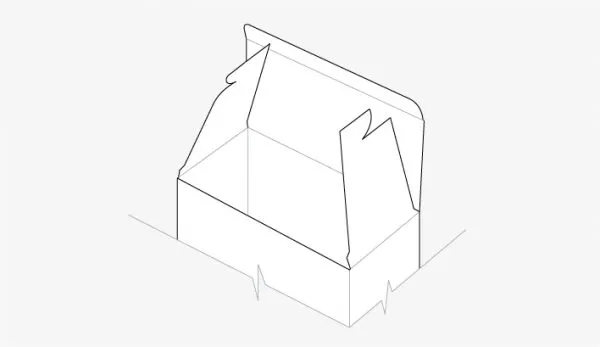

Box Features

We meet your packaging needs with a variety of box structure designs with multiple opening methods, including automatic bottom boxes, latch type and magnetic closure, ensuring that your product packaging is both practical and innovative.

Top & Bottom

Friction Fit Tuck Flap

Slit Lock Tuck Flap

Gusset Tuck

Locked Cap

Full Overlap

Slit Folded Lock

Snap Lock Bottom

Full Auto Bottom

Full Overlap with Tab

Locking Flap

Normal Auto Bottom

Slit Locking Bottom

More Options

Tab Lock

Tongue Lock

Anchor Lock

Corner Punch Out

Hanger

Thumb Notch

Side Hang Tab

Tear Strip

Window Cutout

Mailer Lid

Locking Dust Flap

Hanging Tab

Consult with an Exclusive Customized Packaging Specialist

One-stop service and favorable price

From design to printing, one-stop service saves your time. Provide bulk discounts for wholesalers to reduce purchasing costs.

Excellent printing quality

Advanced printing technology ensures bright colors and clear patterns. Use environmentally friendly materials to show corporate social responsibility.

Volume discounts

We offer competitive prices and volume discounts to reduce your purchasing costs and increase profit margins.

Flexible Logistics Arrangement

We cooperate with a number of logistics companies to ensure that your goods can be delivered to their destinations safely and on time.

Get Started with GPPacking!

We always want to make sure our customers get the best price, so please let us know what you are interested in and we will provide a quote!