- Home

- Custom Mailer Boxes Manufacturer

Custom Mailer Boxes Manufacturer

Wholesale custom mailer boxes for small to medium brands and individuals, let the printed packaging experts help you boost your brand. Low MOQ, factory prices and fast shipping.

Custom Size

Low Moq

360° design

Sustainable

Full-color printing

Get Started with GPPacking!

We always want to make sure our customers get the best price, so please let us know what you are interested in and we will provide a quote!

Customized Packaging From Mailer Box Manufacturer

- Material: Kraft paper,Paper board, Art paper,Corrugated board,Coated paper, etc

- Size: L*W*H (cm) According to customers' specific request.

- Color: CMYK litho printing, Pantone color printing.

- Finishing: Glossy/Matt Varnish, Glossy/Matt Lamination, Gold/sliver foil stamping, Spot UV,Embossed,etc.

- Thickness: 2-2.5mm

- Accessories: Magnet, ribbon, EVA foam, plastic tray, sponge, blister, velvet

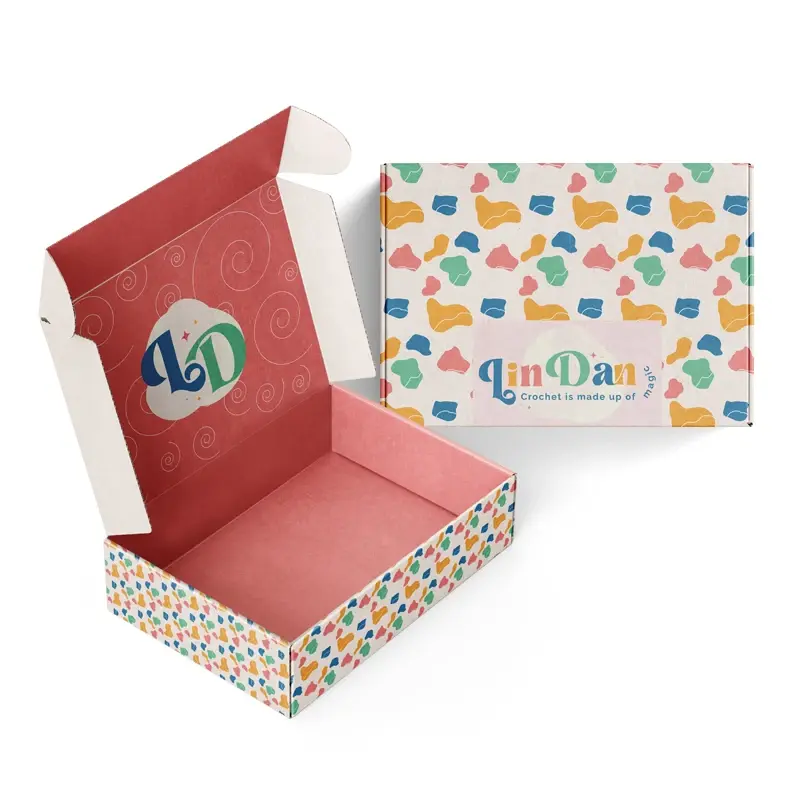

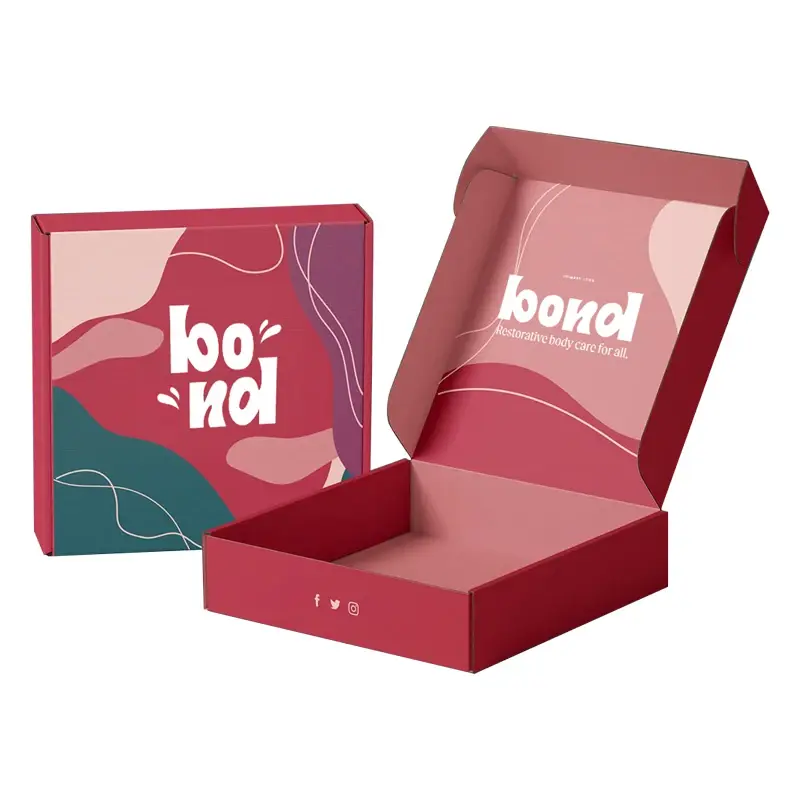

Custom Mailer Boxes Inspiration

Our custom boxes are tailored for a variety of products and industries, from chic elegance to creative unboxing experiences, to elevate your brand with impressive packaging.

Superior Strength Custom Mailer Boxes

Our mailer boxes stand out from competitor packaging through premium construction and materials that boost durability, rigidity and compression resistance for secure transportation and storage.

Photographic quality up to 1200 DPI

Vivid, high definition graphics

We print stunning, true-to-life graphics and branding in full HD directly onto mailer box to make memorable first impressions. Quality imagery drives emotional connections.

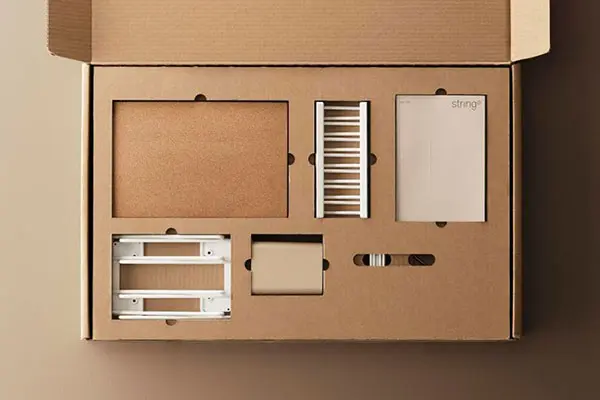

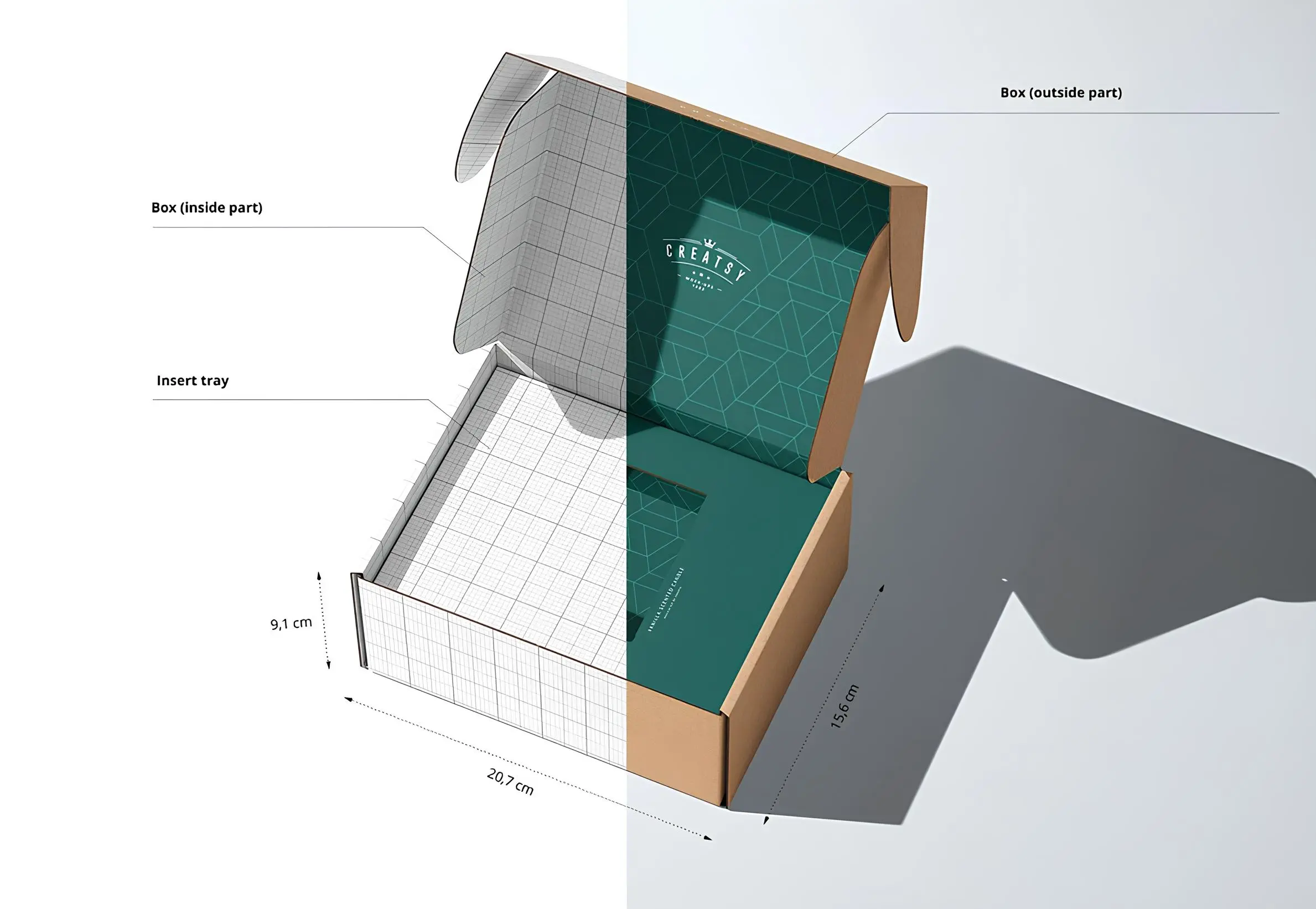

Custom Your BoxPerfect Fit for Your Product

Enhanced Customer Engagement

Distinguish your brand with a personalized unboxing experience. Our customization includes personalized inserts and messages, enhancing customer engagement and creating a memorable interaction with your product.

Custom Your BoxPrinted Branding Features

Logo and Brand Information

Integrate your brand identity seamlessly with our customized mailer boxes. Utilize printed branding features, including your logo and brand information, to create a lasting impression and enhance brand recognition during the unboxing experience.

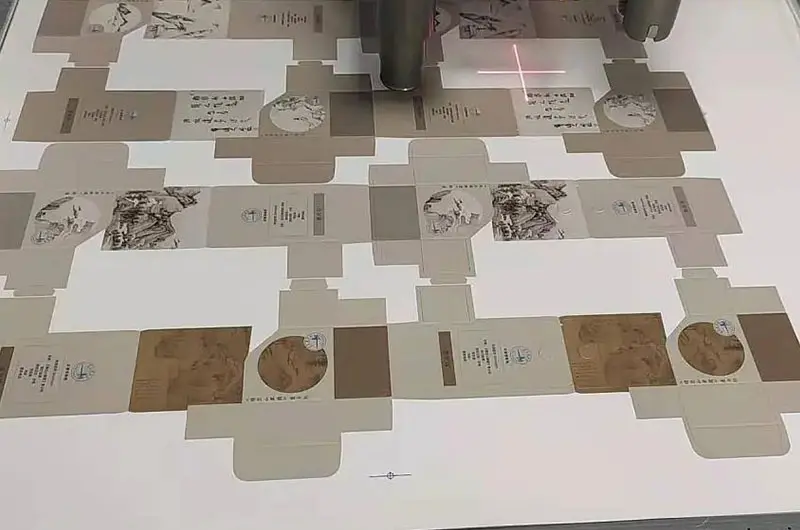

Custom Your BoxPrecise cutting

Ensure perfect fit

Our Mailer Boxes are made with fine craftsmanship to ensure that each part is precisely cut and fits perfectly, whether it is folded or assembled, it can be done easily, ensuring the quality and aesthetics of the product box.

Custom Your Box

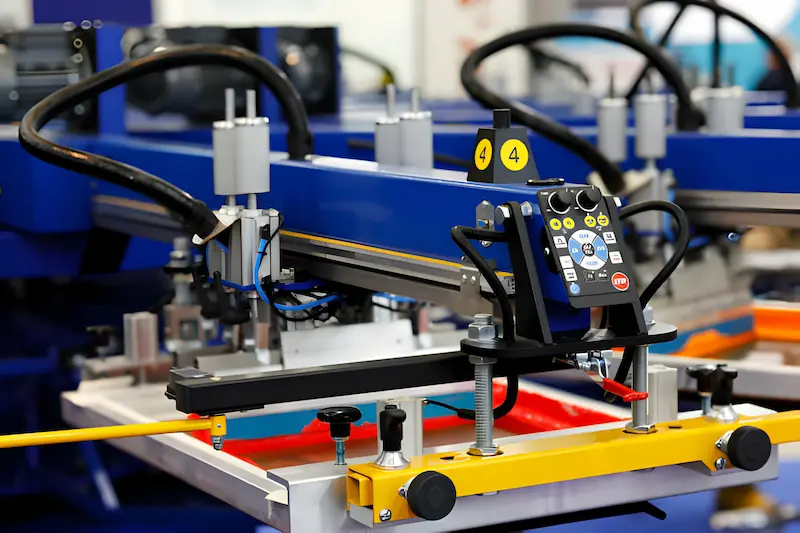

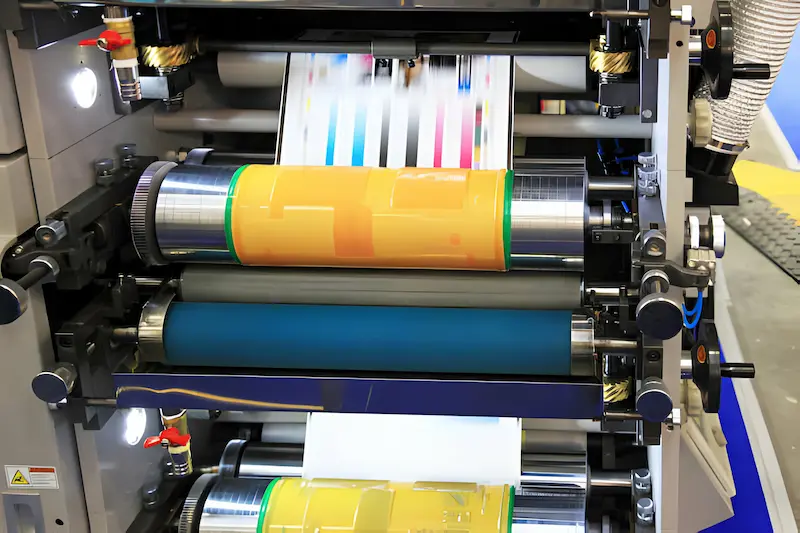

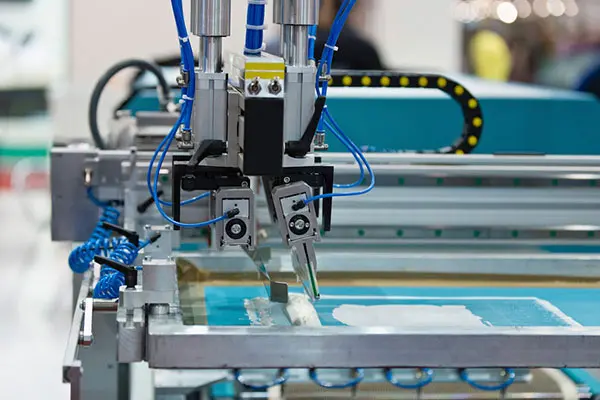

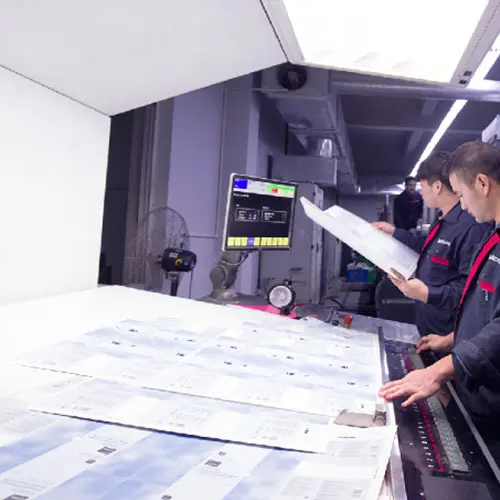

Superior Box Printing Technology

With our mastery and proficiency in offset printing, flexographic printing, gravure printing, screen printing, digital printing, and UV printing, you get accurate colors, layouts, and high-definition printing for every box.

Offset Printing

- 4-5 colors with CMYK + spot colors

- Photo quality printing with smooth gradients

- Effective for long, multi-page book printing

Learn more about offset printing

Screen Printing

- Up to 7 colors with simulated effects like glitter

- Ideal for high density printing with thick ink

- Cost effective for bold prints on 3D surfaces

Learn more about Screen Printing

Digital Printing

- Full color CMYK for short runs

- Variable data and on-demand small batch printing

- Speedy turnaround without setup costs

Learn more about Digital Printing

UV Printing

- Up to 6 colors for outdoor durability

- Down to 8pt micro text printing

- Glossy, vibrant output with quick drying times

Learn more about UV Printing

Flexographic Printing

- Up to 10 colors in CMYK plus spot colors

- Print directly onto paper, card stock & cardboard

- Great for high volume paper/cardboard packaging

Learn more about Flexographic Printing

Gravure Printing

- Up to 12 colors for photorealistic quality

- Consistent across millions of impressions

- Intricately sharp detail for subtle gradients

Learn more about Gravure Printing

Can’t Find Ideal Custom Packaging For Your Industries?

We provide custom solutions to all our customers and offer free pakcing samples that you can take advantage of.

Customize Your Mailer Boxes From a Chinese Manufacturer

With our extensive library of customization options, there is no limit to the amount of inspiration you can put into perfecting your customized box.

Paperboard

Standard paper material, a singular layer of high quality, is ideal for versatile applications such as packaging and printing.

Rigid Board

Gray particleboard has a sturdy structure and is commonly used for packaging due to its recyclable nature, providing an environmentally friendly option.

Corrugated Paper

Triple corrugated board is extremely durable and provides excellent protection. We offer you a wide range of thicknesses from A corrugated to G corrugated.

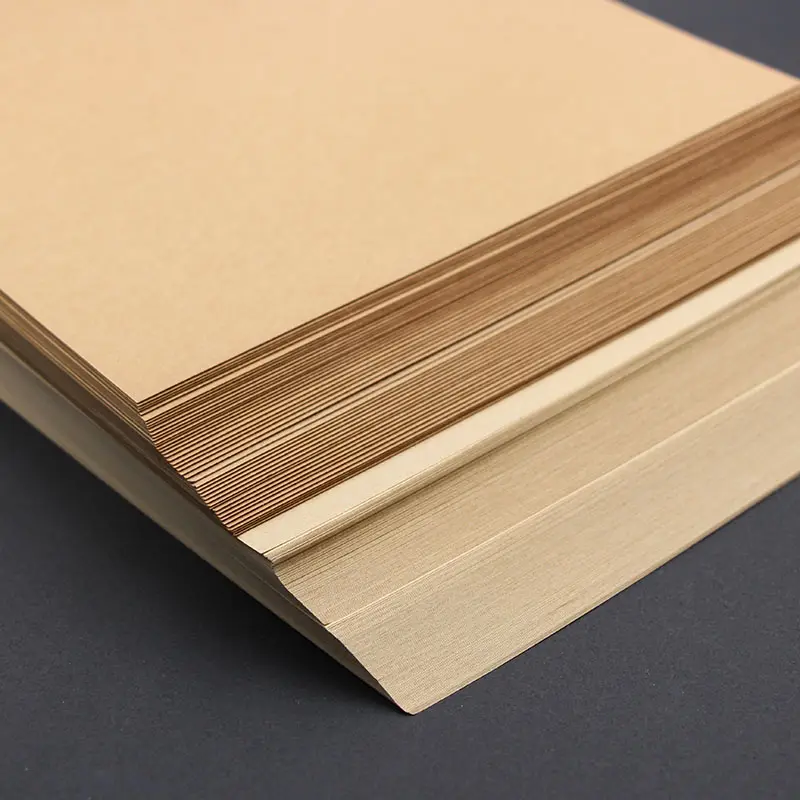

Natural Kraft Paper

Often used for eco-friendly packaging, made from unbleached wood pulp, it boasts a natural, earthy appearance and is easily recyclable.

Offset Printing

Ink is transferred from the printing plate to the blanket and then to the printing surface, allowing for high quality printing in large quantities.

Screen Printing

The ink is applied to the surface of the box through a mesh screen. This method allows for detailed and colorful designs that are suitable for custom packaging.

Digital Printing

Printing designs directly onto packaging materials using electronic transmission. It offers flexibility, cost-effectiveness and customization for smaller print runs.

UV Printing

Uses UV light to cure the ink immediately producing vibrant colors, enhanced durability and a glossy finish.

Flexographic Printing

Transferring ink to various substrates, such as cardboard boxes, using flexible letterpress plates is a common and efficient way to print large quantities with versatility and high quality.

Gravure Printing

Printing with rubber plates has the advantages of light printing pressure, high printing quality, wide range of applications, etc., and can achieve bright colors and delicate images.

Lasers engraving

The laser makes small cuts and engravings on the packaging material, cutting through the surface of the box and generating a skeleton pattern to form beautiful graphics.

Water-based Ink

An eco-friendly ink, with water as solvent, suitable for all kinds of printing, especially for food, medicine and other packaging printing with strict hygiene requirements.

Vegetable Ink

100% eco-friendly, soybean, flax and other plant-based inks are harmless to the environment and human health, and can be printed in vibrant colors.

Oil-based inks

Composed of oil and pigment, it produces bright colors and clear patterns. Its good adhesion and weather resistance maintains stable quality in various environments.

Fluorescent Color Ink

It can emit visible light under UV light irradiation, with bright and saturated colors to attract people’s attention. Meanwhile, it has certain anti-counterfeiting performance.

Pantone

Standard color card, can ensure the consistency of the color of the printed materials, improve the printing effect, make the product more attractive.

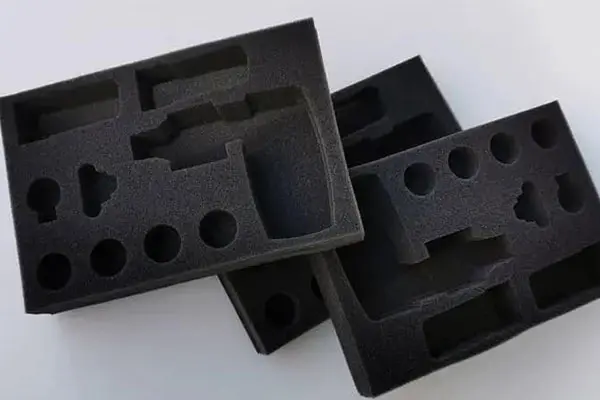

EVA insert

EVA inserts can be molded 1:1 according to the shape of the product. It has good elasticity, flexibility, anti-stamping, and can well protect the goods from damage by external factors.

$$$$

Sponge & Pearl Cotton Insert

Sponge is a kind of porous material, rich in good ductility and elasticity, good protection of fragile goods. Pearl cotton is made of low-density polyethylene resin through physical foaming to produce countless independent air bubbles.

$$

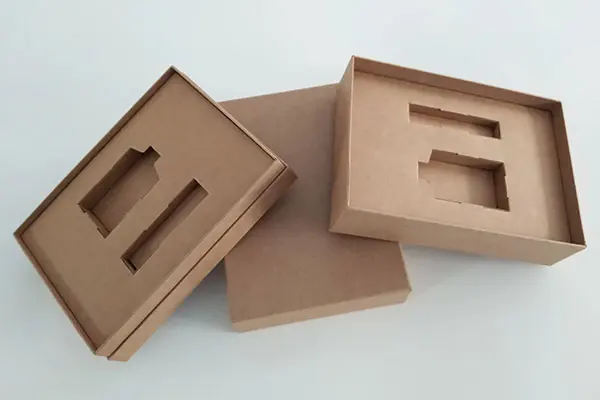

Cardboard insert

Cardboard inserts are eco-friendly, easy to load and unload, and can be die-cut into various shapes of grooves to hold products in place.

$

Blister & paper-molded insert

Blister inserts are made from 1:1 injection molding and are more stable and compression-resistant than other inserts. The paper-plastic inserts are the newest environmentally friendly inserts, made of paper and fiber pulp, and are most commonly used for cell phone inserts.

$$$

Embossing

The surface shows raised patterns and textures with obvious relief three-dimensionality, which enhances the artistic infectivity of the printed matter

Debossing

The surface shows concave patterns and textures with obvious relief three-dimensionality, which enhances the artistic infectivity of the printed matter

spot UV

Curing localized UV coating in designated areas, matte or glossy, to enhance the three-dimensionality and artistic effect of the pattern.

UV Vanish

Curing the ink by UV irradiation makes the surface smooth and glossy. It enhances color, glossiness.

Gold & Silver Foil

Transfer different metal foils, such as gold, silver, etc. to the surface of the package by thermal transfer, forming a unique metallic luster.

Lamination

On the surface of the packaging coated with different materials of the protective film to make it more texture and aesthetics, and increase its moisture-proof, tear-proof and other properties.

Stencil

Translucent engraving processing background or let the hollowed out part become a pattern. It allows consumers to visualize the product and increase the attractiveness of the product.

laser

It can produce holographic patterns, rainbow luster unique visual effects on the box, with high resolution and accuracy, applicable to a variety of materials.

Let GPPacking Help Your Brand Stand Out

High Definition Printing for Accurate Brand Colors

Our state-of-the-art printing presses allow for sharp, vivid colors and crisp, clear text on every box.

- Vibrant offset and digital printing

- Flawless reproduction of graphics

- Striking metallic accents and embossing

- Smooth gradient backgrounds

- Precision alignment of colors and details

- Box styles ideal for your product

Finishing that enhances the texture of your brand

All printed boxes undergo specialist finishing touches from our skilled team to give a clean, professional look.

- Robust matte & gloss UV coatings

- Beautiful foil stamping

- Superb scuff and tear resistance

- Dimensional die-cut shapes

- Clean folded edges and construction

- Sturdy construction carrying weighty products

Choosing sustainable packaging solutions

We use certified paper stocks from responsible sources, renewable plant-based inks, and recycling programs to minimize waste.

- Optimized material usage and minimal wastage

- Ethical sourcing of renewable materials

- Customizable recyclable paperboards

- Soy and mineral oil-based inks

- Solvent recycling procedures

- Continuous advancement of green processes

One-stop solution for SMEs' product packaging customization problems

We have been pursuing the innovation of technology and process, we strictly select high-quality raw and auxiliary materials and supporting resources, we insist on learning and self-improvement, from the moment you choose GPPacking, the wonderful story has happened.

One-stop custom mailer boxes service

The combination of competitive pricing, quality control, scope of customization, accelerated delivery and commitment to sustainability puts our custom box manufacturing capabilities in an advantageous position.

Accuracy

We utilize advanced die cutting equipment able to precisely cut cardstock to within a 0.5mm tolerance for folds, slots, and box dimensions. We verify accuracy during our quality assurance checks using templates, gauges and calipers.

Print Quality

Our 6-color offset printers and high resolution digital presses produce packaging with vibrant, accurate colors and crisp readable text as small as 4-point fonts. We match 98% of Pantone and CMYK color preferences and requirements during press checks and proofing.

Material Quality

We use thick corrugated cardboard with a tested breaking strength of 200-400 psi, manufactured by trusted suppliers we've worked with for more than a decade to ensure a reliable source of inventory. We also offer custom paper stocks such as kraft, white, and recycled materials.

Packaging Protection

Mailers come with interior padding options like foam, air pillows, and paper cushioning that provide shock and vibration absorption during sorting and shipping. Sturdy outer construction protects against typical impacts, pressure and elements packages encounter.

Price

We offer prices at least 10-20% below major competitors in the market, made possible through strategic partnerships with paper suppliers and bulk purchasing power.

Customization

With a full in-house design team and high-resolution digital and offset printing presses, we facilitated over 3,000 unique packaging box designs last year serving B2B and B2C clients across various industries and use cases.

Turnaround Time

Over 75% of our orders meet the standard 15 day delivery. For expedited service, we fulfill 85% of 7-day orders.

Sustainability

Currently over 30% of material volume is from recycled paper stocks and another 20% from sustainably harvested virgin fibers, enabling us to cater to eco-conscious brands.

Customized mailing boxes for your products

At GPPacking, we are proud to offer a wide selection of over 500 in-stock wholesale mailing box designs and styles, all of which can be found in our fully equipped warehouse. Our diverse range of mailing boxes meets the needs of many industries including retail, beauty, food, beverage and electronics.

Cosmetic packaging box

Cosmetic

Jewelry Packaging Box

Jewelry

shipping Packaging Box

shipping

Food Packaging Box

Food

Jewelry Packaging Box

Jewelry

Gift Packaging Box

Gift

cloth Packaging Box

cloth

Consumer Packaging Boxes

Consumer

Electronic Packaging Box

Electronic

Custom Mailer Boxes That Fit Your Brand

Custom mailer boxes based on your preferred size and design. A wide range of internal box sizes and materials are available.

Trusted Chinese Mailer Box Supplier

Our technical and industrial teams offer a wealth of expertise to support you in defining your printed packaging projects and ensure perfect compatibility between our packaging and your products and brands, thus guaranteeing our mutual success.

- 20 years of experience creating innovative, sustainable packaging for 500+ brands globally.

- 10+ skilled designers on staff using latest 3D modeling and rendering technology.

- 30 enterprise-grade printing and decorating machines, including 18 digital inkjet and flexographic printers.

- Proven track record with 95% on-time delivery rate thanks to streamlined logistics.

- Onsite quality control lab and testing at every stage of the production process.

- Strategic partnerships with raw material suppliers to mitigate supply chain risks.

- Flexible production process, support for small batch customization, to meet personalized needs.

- With eco-friendly materials, our designs align with environmental values.

what makes us different

Premium service you won't experience with other providers

Speed

Our fully automated production floor enables us to deliver initial packaging prototypes in 5 days as well as reduce average production cycles by 8 days compared to the industry standard.

Quality

In addition to a <1% defect rate, we employ microsensor scanning to ensure each dimension adheres within 0.2mm of specifications.

Range

We offer over 50 customizable box materials from sustainably-sourced paperboard to luxe metals and acrylics, along with more than 100 customizable finishes and production capabilities.

Sustainable Solutions

Our product range incorporates the latest innovations such as recycled inks, renewable grommets and fully compostable materials. We offer extensive consulting to help our customers achieve their ecological goals.

Innovation

We continually re-invest 12% of profits into R&D, having pioneered enhancements this year alone like antimicrobial coatings, user-replaceable plastic films, and paper-foam composites.

Cost Savings

Box customization through our end-to-end capabilities provides efficiency benefits reflected in savings of 15-30% for 70% of customers compared to alternatives.

FAQ Of Custom Mailer Boxes

Do you have questions about custom mailer boxes? We have a list of frequently asked questions below. If you have more inquiries beyond what you can find here, our customer support is ready to answer them, 24/7.

What is the process of customizing mailer boxes?

First, you provide your design requirements or choose one of our templates. Next, we do design confirmation and then produce samples for your review. After approval, mass production begins and final packaging is shipped.

What types of materials do you offer for custom mailers boxes?

We offer corrugated cardboard, Kraft, paperboard, rigid plastics, and more.

What information do I need to provide to customize the box?

Please provide product size, weight, design requirements (such as color, pattern, LOGO, etc.) and expected delivery date.

How long does it take to customize the packaging box?

From design confirmation to production completion, it usually takes 2-4 weeks, depending on the order size and complexity.

What is the minimum order quantity for custom packaging boxes?

The minimum order quantity is usually 500 pieces, but the specific quantity may be adjusted based on design complexity and material cost.

Can I request samples?

sure. We will make samples for you to confirm the design and quality before mass production.

How is the cost of custom packaging boxes calculated?

The cost is calculated based on factors such as design complexity, material cost, production quantity and delivery time.

How do I measure the inside dimensions of my mailer boxes?

when it is opened towards you:

The length is measured from the left side of the box to the right side.

Width is measured from the front to the back of the box.

Depth is measured from the top to the bottom of

Ask for a

quote today

We offer a one-stop packaging service, backed by packaging experts and more than 20 years of packaging industry research.