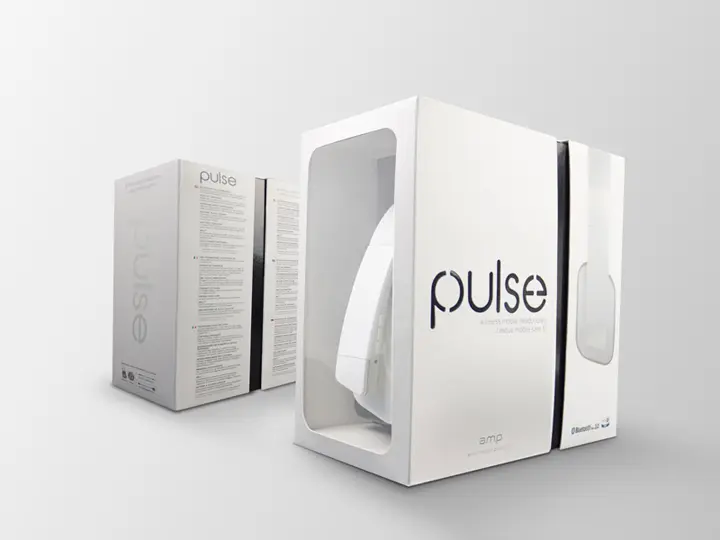

We craft not just boxes, but brand stories. Choose GPPacking custom packaging boxes and make every unboxing an unforgettable experience.

With a tailored one-on-one consultation, you will receive a personalized experience from conception to production and delivery. Our mission is to provide you and your customers with an exceptional unpacking experience.

Get professional packaging and printing to boost your branding and marketing.

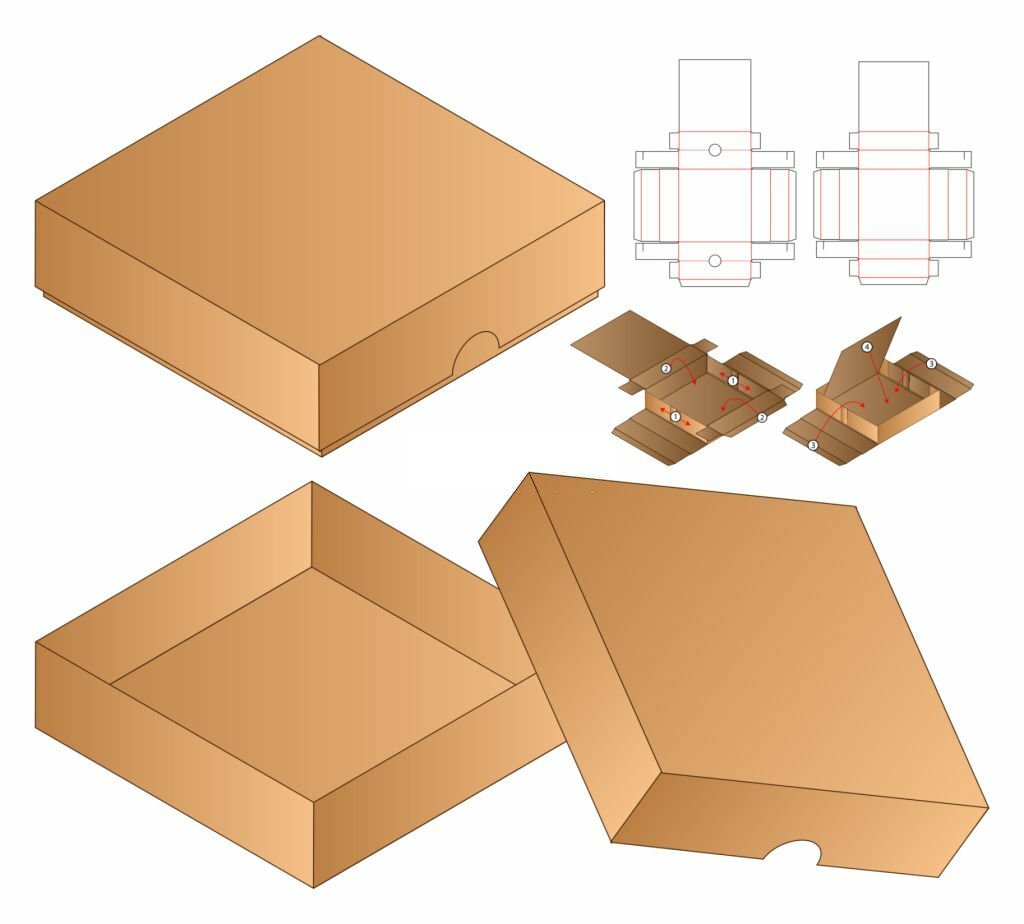

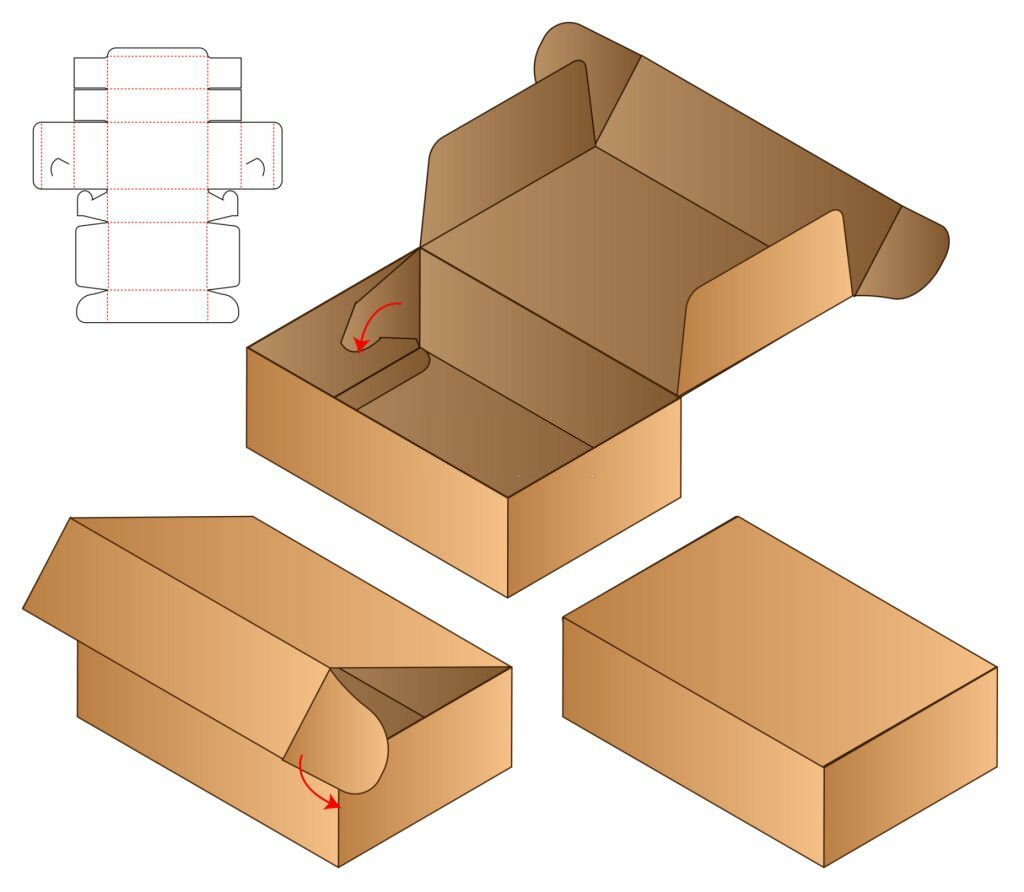

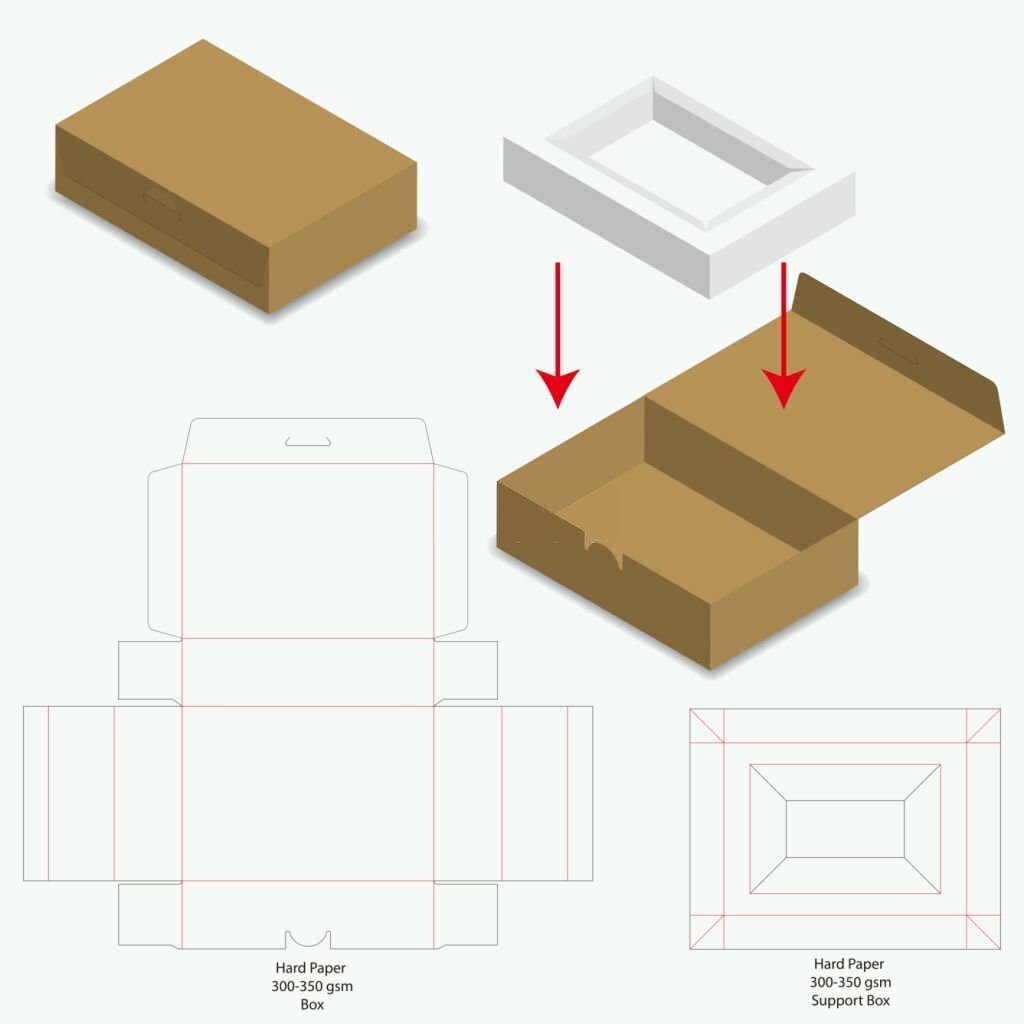

Variety of box styles and premium options

No minimum quantity

Get instant pricing

Full-color printing inside & out

Sturdy and durable packaging solution

Premium feel and appearance

Customizable sizes and shapes

Embossing and debossing options available

Exceptional strength and durability

Custom sizes and thickness options

Full-color printing for product information

Custom inserts and dividers

Sustainable materials and printing processes

Recyclable and biodegradable options

Eco-conscious design consultation available

Compliance with environmental standards

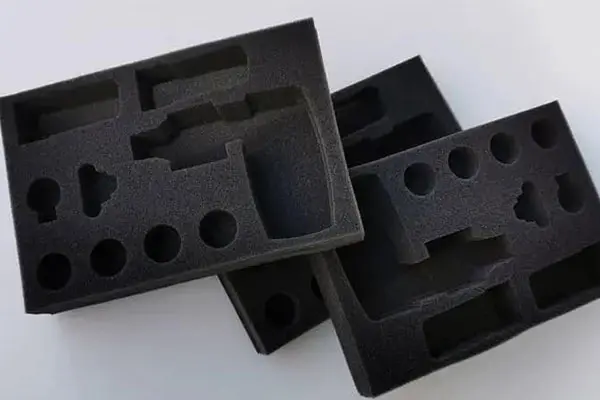

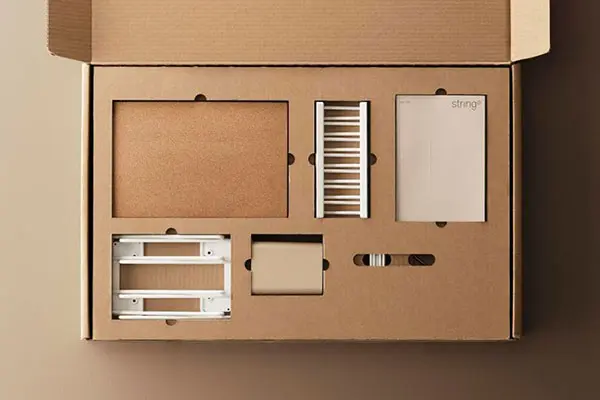

Diverse materials (foam, cardboard, molded pulp) Elevates product presentation and unboxing Tailored for single or multi-item packaging Offers easy removal and reusability

Our powerful and diverse custom packaging box services include cartons, corrugated boxes, plastic packaging, environmentally friendly materials, gift boxes, envelopes and special shape designs.

We strive to deliver your customized packaging on time, within budget, and with an exceptional level of quality.

use high quality and environmentally friendly raw materials, in line with international safety testing standards

20 years of professional packaging design and planning team, specializing in high-grade packaging of precious commodities.

Senior craftsmen strictly control the craftsmanship, quality engineers strictly control the product.

Order specialists are responsible for the system, rapid response system to ensure that the completion of customer order requirements

Powerful after-sales team to follow up the return visit, packaging in the storage and use of the transportation process counseling

We provide custom solutions to all our customers and offer free pakcing samples that you can take advantage of.

With our extensive library of customization options, there is no limit to the amount of inspiration you can put into perfecting your customized box.

Standard paper material, a singular layer of high quality, is ideal for versatile applications such as packaging and printing.

Gray particleboard has a sturdy structure and is commonly used for packaging due to its recyclable nature, providing an environmentally friendly option.

Triple corrugated board is extremely durable and provides excellent protection. We offer you a wide range of thicknesses from A corrugated to G corrugated.

Copperplate paper has a smooth and glossy surface, and the color is brilliant after printing. It is divided into single copper and double copper, and is commonly used in color boxes.

Embossed papers have a raised pattern or texture created through a pressing process. This technique enhances the visual and tactile appeal of the paper.

leatherette paper is a synthetic material similar to genuine leather. It provides a cost-effective alternative to leather look on packaging boxes.

Soft touch paper is characterized by its velvety texture and has a smooth, luxurious feel. Ideal for high-end and jewelry packaging.

Glossy and smooth, used for producing paper bags, rigid cardboard gift boxes, magazine printing and paper manual printing.

Ink is transferred from the printing plate to the blanket and then to the printing surface, allowing for high quality printing in large quantities.

The ink is applied to the surface of the box through a mesh screen. This method allows for detailed and colorful designs that are suitable for custom packaging.

Printing designs directly onto packaging materials using electronic transmission. It offers flexibility, cost-effectiveness and customization for smaller print runs.

Uses UV light to cure the ink immediately producing vibrant colors, enhanced durability and a glossy finish.

Transferring ink to various substrates, such as cardboard boxes, using flexible letterpress plates is a common and efficient way to print large quantities with versatility and high quality.

Printing with rubber plates has the advantages of light printing pressure, high printing quality, wide range of applications, etc., and can achieve bright colors and delicate images.

The laser makes small cuts and engravings on the packaging material, cutting through the surface of the box and generating a skeleton pattern to form beautiful graphics.

An eco-friendly ink, with water as solvent, suitable for all kinds of printing, especially for food, medicine and other packaging printing with strict hygiene requirements.

100% eco-friendly, soybean, flax and other plant-based inks are harmless to the environment and human health, and can be printed in vibrant colors.

Composed of oil and pigment, it produces bright colors and clear patterns. Its good adhesion and weather resistance maintains stable quality in various environments.

It can emit visible light under UV light irradiation, with bright and saturated colors to attract people’s attention. Meanwhile, it has certain anti-counterfeiting performance.

Standard color card, can ensure the consistency of the color of the printed materials, improve the printing effect, make the product more attractive.

EVA inserts can be molded 1:1 according to the shape of the product. It has good elasticity, flexibility, anti-stamping, and can well protect the goods from damage by external factors.

$$$$

Sponge is a kind of porous material, rich in good ductility and elasticity, good protection of fragile goods. Pearl cotton is made of low-density polyethylene resin through physical foaming to produce countless independent air bubbles.

$$

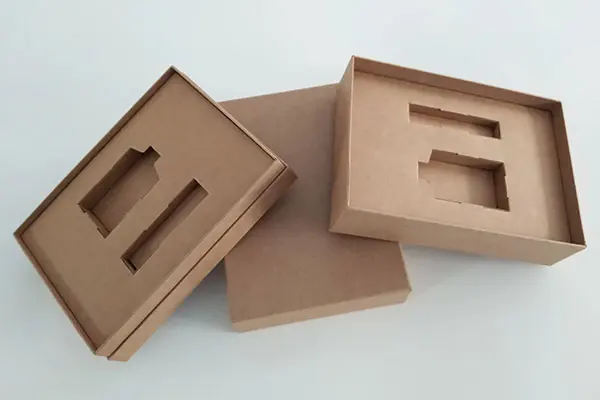

Cardboard inserts are eco-friendly, easy to load and unload, and can be die-cut into various shapes of grooves to hold products in place.

$

Blister inserts are made from 1:1 injection molding and are more stable and compression-resistant than other inserts. The paper-plastic inserts are the newest environmentally friendly inserts, made of paper and fiber pulp, and are most commonly used for cell phone inserts.

$$$

The surface shows raised patterns and textures with obvious relief three-dimensionality, which enhances the artistic infectivity of the printed matter

The surface shows concave patterns and textures with obvious relief three-dimensionality, which enhances the artistic infectivity of the printed matter

Curing localized UV coating in designated areas, matte or glossy, to enhance the three-dimensionality and artistic effect of the pattern.

Curing the ink by UV irradiation makes the surface smooth and glossy. It enhances color, glossiness.

Transfer different metal foils, such as gold, silver, etc. to the surface of the package by thermal transfer, forming a unique metallic luster.

On the surface of the packaging coated with different materials of the protective film to make it more texture and aesthetics, and increase its moisture-proof, tear-proof and other properties.

Translucent engraving processing background or let the hollowed out part become a pattern. It allows consumers to visualize the product and increase the attractiveness of the product.

It can produce holographic patterns, rainbow luster unique visual effects on the box, with high resolution and accuracy, applicable to a variety of materials.

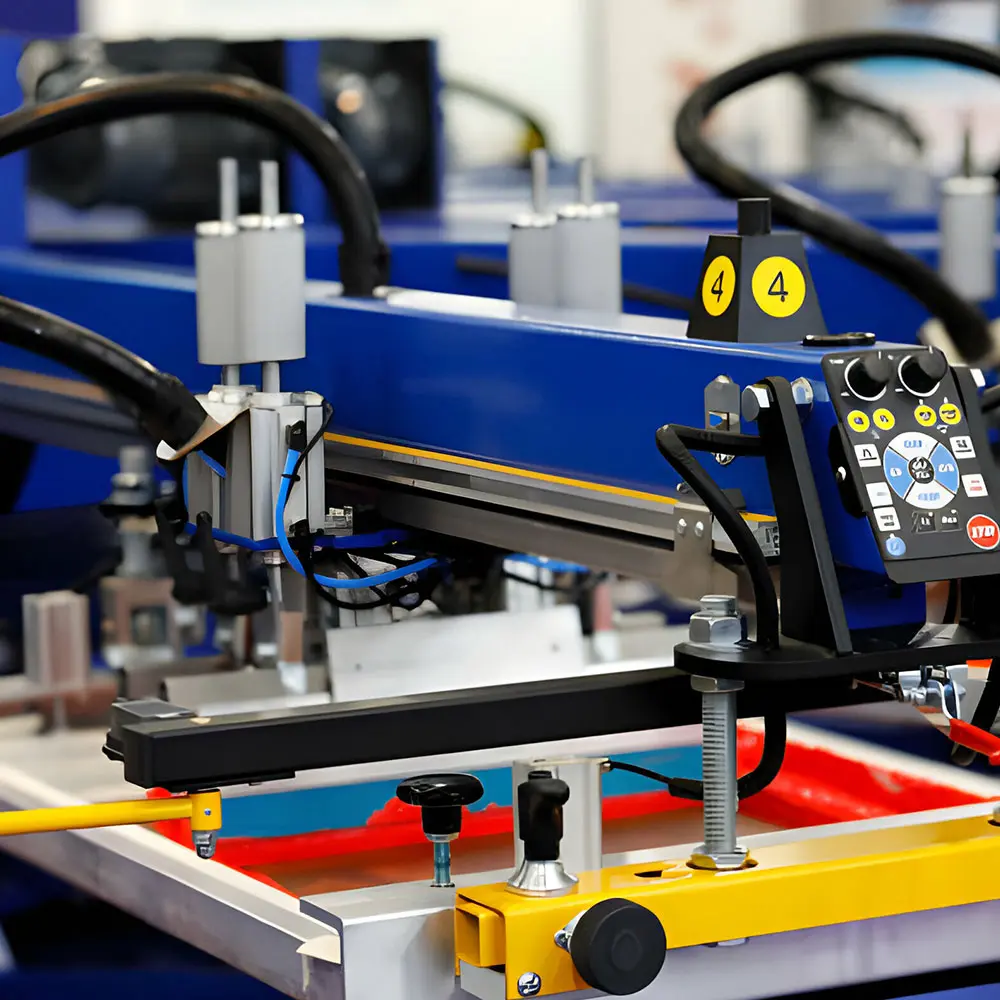

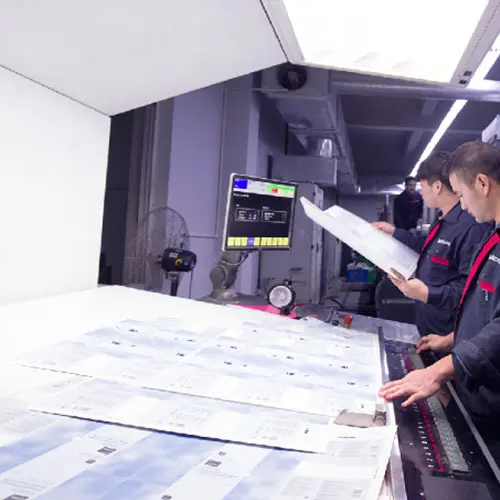

With our mastery and proficiency in offset printing, flexographic printing, gravure printing, screen printing, digital printing, and UV printing, you get accurate colors, layouts, and high-definition printing for every box.

Offset printing is a lithographic printing technique capable of printing from a single color to as many as six colors (including spot colors), and is commonly used for high-quality box printing.

Flexographic printing is a flexible printing technology capable of directly printing up to 10 colors with vibrant colors, rich details and consistent printing results.

Screen printing is a printing technique by means of screen stencils, capable of single to multi-color printing, usually no more than 6 colors. In box printing, screen printing provides clear, vibrant graphics suitable for large area coverage and special effects.

Digital printing technology offers flexible color options, often capable of printing up to four colors (CMYK) or more. Crisp and vibrant printing on boxes lends itself to personalization and small production runs, but can be slightly more costly than traditional printing

UV printing offers high gloss and abrasion resistance in packaging and typically supports four-color (CMYK) printing with the addition of spot or metallic colors. Printing on boxes with bright, long-lasting colors is suitable for high-end packaging, but at a higher cost.

Gravure printing is suitable for high volume production and can be printed in a variety of colors, usually including four colors (CMYK) and more. Fine printing effect on boxes with full colors, but relatively high cost and environmental impact.

An appealing package that captures the essence of a brand makes a memorable first impression on shoppers and can serve as a value-adding touchpoint between product and consumer.

Unique, customized boxes help products stand out on crowded shelves next to competitors with generic packaging.

Packaging that reflects a cohesive brand story and visual identity reinforces what a brand stands for each time a customer interacts with the product.

Creative packaging in a brand's recognizable house style triggers an emotional response and sense of familiarity, nurturing customer relationships over time.

Packaging tailored for a specific product, cohort, or occasion better accommodates the item inside and suits customers' preferences and use cases.

Intriguing textures, finishes, opening mechanisms and supplementary info engage customers more deeply during unboxing and use.

Custom inserts, sleeves, and compartments designed for an individual item improve protection, portability, display and access to the contents.

Details like soft-touch lamination, foil stamping and sturdy construction signal superior quality and luxury.

Customization offers the possibility for boxes designed specifically for efficiency, recyclability and reduced waste.

With GPPacking’s 10+ years of packaging experience covering over 60 industries and 2,000+ design examples, you can rest assured that your ideas will be given to us and realized for you.

Our printing process can reproduce colors with striking accuracy and vibrancy to perfectly match your brand palette. We'll collaborate to determine ideal pantone colors and finishes to make the hues pop.

We can integrate slogans, logos, or other defining text in a clean, minimalist way that uniquely captures your brand voice. Location and scale are customized to find the right emphasis.

Work with our graphic artists to brainstorm creative concepts that aestheticly communicate your brand. Abstract shapes, textures, fonts all tailored to your style.

Elevate through small touches like ceremonial ribbons, delicate patterns inspired by details from your product line, or even a subtle background watermark of your logo.

Showcase product imagery, ingredients, or behind-the-scenes shots to resonate with your customers and highlight what your brand values most.

Linen, matte, spot UV and other embellishments tailored so that your customers can start perceiving your brand the moment they pick up the box.

GPPacking is a large-scale comprehensive packaging enterprise with a long history, the group is supported by printing and packaging factories, professional gift box packaging, carton box packaging, leather box packaging and other high-grade packaging custom manufacturers, focusing on high-quality packaging and high-quality printing personalization.

Prior to design, our team researches packaging trends, competitor landscape and your target consumer needs. This leads to optimal packaging offerings that meet market needs. The results are aligned with your brand objectives.

We work with seasoned designers with over 10 years of experience to provide unique and interesting designs that help position your brand accurately in the marketplace.

We assist you in designing an impressive packaging structure that enhances your brand based on the form, functionality and effectiveness of your product.

With 8 quality QC inspectors, we have a strict inspection process from printing to finished product shipment with detailed signage. We are attentive, just to make you feel more at ease.

According to your requirements, in addition to customized boxes, we can provide you with a full set of customized solutions such as customized labels, printed brand cards, and packaging paper bags.

We utilize recycled materials, non-toxic inks, and eco-friendly manufacturing processes for minimizing carbon footprint. This aligns with ethical and green business practices.

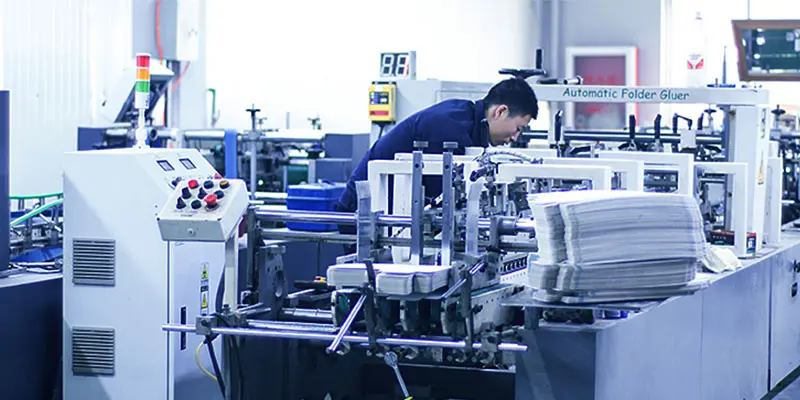

All of our manufacturing processes are done at our production facility, which allows us to shorten lead times and deliver solutions on time.

We believe in working with you, which is why we offer after-sales services. They are designed to help you in times of trouble and remain effective throughout the life of your product.

With our extensive library of customization options, there is no limit to the amount of inspiration you can put into perfecting your customized box.

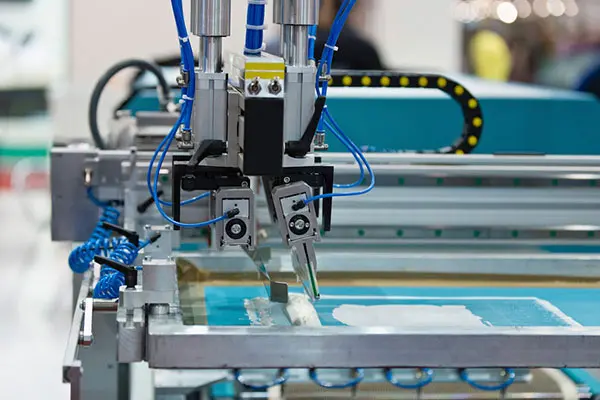

We adopt advanced CPT plate making technology to ensure the excellent quality of printed materials. During the production process, we strictly carry out color proofreading and test printing, and strive to provide you with high-quality boxes that meet the design requirements.

We have advanced printing equipments such as Roland and Heidelberg printing, supporting 1.7m roll paper slitting machine and full-open face paper cutter; we have various specifications of rolls of paper, which can be slit according to your needs and shorten the order time by 40%.

More than 10 years of industry experience, served customers in more than 50 countries around the world. We are proficient in more than 10 kinds of surface treatment processes, such as embossing, UV coating and hot stamping, etc. and have achieved 98% customer satisfaction.

In addition to the usual glossy and matte films to protect the surface of your packaging, we also have other customized options to add creativity and security markings to our laminating process.

Our die-cutting accuracy is as high as 0.05 millimeters, which effectively ensures the accuracy of box size and shape. In addition, our productivity can reach up to 20,000 boxes per hour per machine.

Our gluing speed is up to 100 boxes per minute, ensuring a quick response to your needs. We also undergo strict quality testing to ensure strong bonding, no breakage, no stains

Color box in addition to the fixed material costs and plate fees, start-up costs, post-process costs, are apportioned to each color box, if the number of color boxes do not reach the number of printers starting order, the cost will be much more expensive.

The paper used for color box production includes coated paper, cardboard and so on. If the quantity purchased is small, the paper mill will consider the cost and development, and may raise the price or refuse to supply, thus leading to the increase of raw material cost.

Color boxes are customized products and user needs vary, including printing content, structure and size. You need to pay a plate fee, which mainly includes printing plates and knife plates. The production cost will be allocated to the unit price of the paper card.

The cost of plate making and printing is fixed, for example, a set of four-color printing plates costs about 400 yuan. Four-color overprinting is required before formal printing. Color adjustment takes 30-40 minutes and consumes 200 sheets of adjustment paper. The larger the print volume, the lower the unit cost; the smaller the quantity, the higher the unit cost.

Post-processing such as lamination, local UV, hot stamping, and die-cutting all require plate making or die cutting, and also require debugging time. Like printing start-up fees, they are fixed costs. If the order quantity is small, the unit price will naturally be expensive.

Rest assured, we welcome orders of all sizes, including branded and small to medium quantities. We specialize in personal customization and guarantee the same high-quality print as larger establishments.

A supplier that has been deeply involved in the printed packaging industry

In the last 20 years, we've made it happen:

Over 20 years in the industry, delivering top-notch printing and packaging solutions.

Reduced client expenses by 15%, offering competitive pricing without compromising quality.

Developed 50+ cutting-edge packaging designs, catering to diverse client needs.

Consistent track record of meeting deadlines, ensuring timely product delivery.

Thanks for always trusting & supporting us.

It depends on the specific design and material. We will provide you with a detailed quote based on your needs, including the minimum order quantity.

We offer a wide range of material options, including cardboard, corrugated board, etc., as well as a variety of finishes, such as matte, glossy, foil stamping, UV coating, etc. We also offer a wide range of other materials and finishes.

The cost will be calculated based on factors such as design complexity, material selection, order quantity, and any special treatments (e.g. foil stamping, UV coating). We will provide you with a detailed quotation so that you can understand every cost.

We offer a wide range of customized sizes and shapes, whether it's a standard size or a special customization, we can meet your needs.

Yes, we can add special features such as magnetic closure, reusable tape closure, etc. according to your needs.

The design time depends on the complexity of the design, usually we will provide a preliminary design draft as soon as we receive your detailed requirements.

The materials we use and the manufacturing process comply with international environmental standards, such as FSC certification, to ensure that your packaging is environmentally friendly.

Yes, we will make samples before mass production for you to check the design, material and printing effect to ensure the final product meets your expectation.

We encourage sustainable packaging and can offer options for recycled or biodegradable materials to help your brand achieve its environmental goals.

From design to printing, one-stop service saves your time. Provide bulk discounts for wholesalers to reduce purchasing costs.

Advanced printing technology ensures bright colors and clear patterns. Use environmentally friendly materials to show corporate social responsibility.

We offer competitive prices and volume discounts to reduce your purchasing costs and increase profit margins.

We cooperate with a number of logistics companies to ensure that your goods can be delivered to their destinations safely and on time.

We always want to make sure our customers get the best price, so please let us know what you are interested in and we will provide a quote!