Custom Box

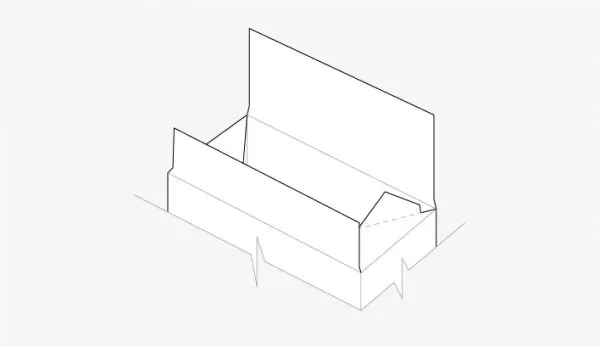

structural design

Our team of professional structural designers and engineers tailor the box structure and die-cut lines to your specific needs. Packaging design that perfectly fits your brand image.

- Home

- Custom Packaging Services

- Structural Design

What is box structure design

Structural design refers to the engineered construction and integrity of a printed packaging box to make it sturdy, protective, and functionally reliable for its intended contents and purpose.

We provide you with better details

Materials and Wall Strength

Selecting suitable cardboard or corrugated board materials and calibrating the wall thickness and density to offer sufficient strength without excessive bulk.

Locking structures

Structural design might incorporate tabs, tucks, and locking flaps to securely close the box.

Reinforcing edges

Structural weak points are often the corners and edges. Reinforced edges with multiple cardboard layers or metal staples help prevent crushing or tearing.

Load Testing

Structurally testing packaging designs with weighted loads to simulate stacking and compression during transport and storage. This validates the packaging's ability to withstand expected rigors.

Optimized Dimensions

Tailoring packaging dimensions to efficiently fit intended contents while conforming to standard pallet sizes, shipping container spacing, retail shelf space and other practical considerations.

Functional Elements

Adding handles, windows, opening instructions or other ergonomic and brand-focused details as compatible structural elements.

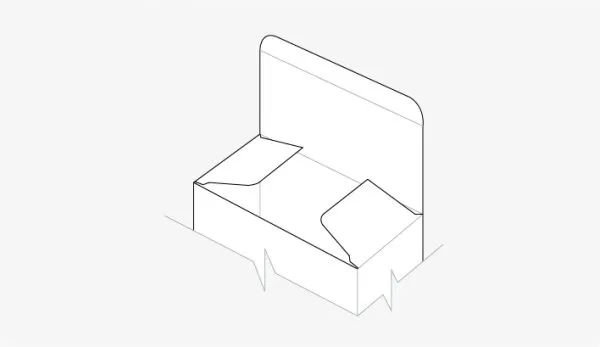

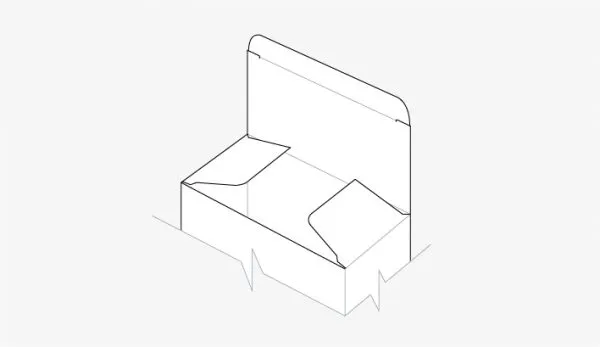

Customized Packaging Opening Experience

We specialize in creating unique packaging opening solutions, including convenient auto-bottom locking, secure magnetic closures, and easy-tear full-flap openings, ensuring a perfect blend of product presentation and user experience. Choose our customization service to make your products stand out in a competitive market.

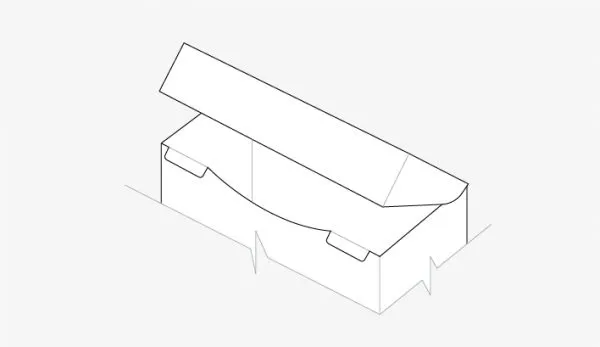

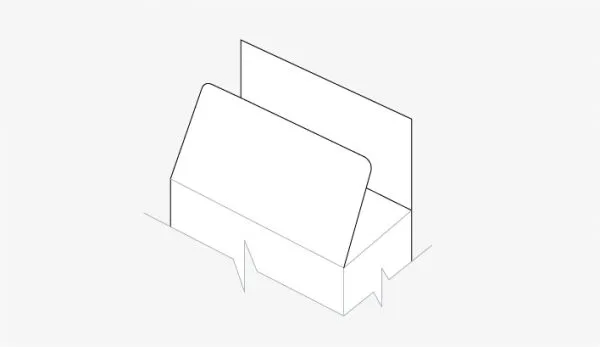

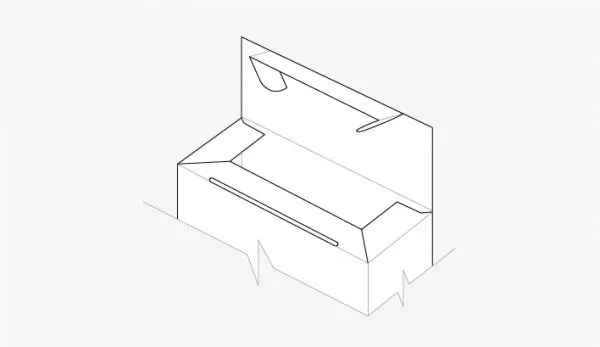

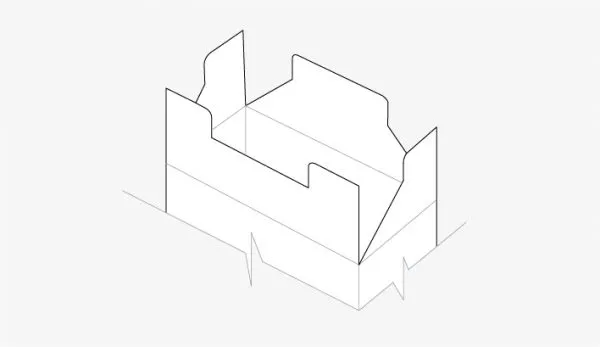

Friction Fit Tuck Flap

Slit Lock Tuck Flap

Gusset Tuck

Locked Cap

Full Overlap

Slit Folded Lock

Snap Lock Bottom

Full Auto Bottom

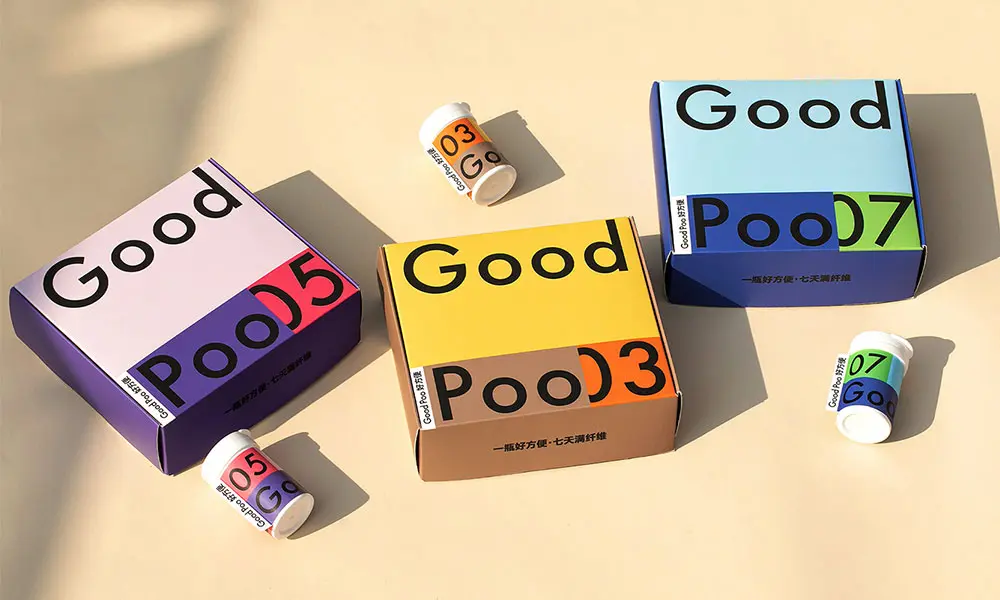

How we can provide you with structural design

We are good at structural innovation, precise printing, exquisite surface treatment, and provide a variety of box type customization to ensure that your packaging design is unique and of excellent quality.

Internal structure

We will design the internal structure according to the characteristics and protection needs of the product. For example, for fragile items, we will design anti-shock cushioning layer, such as foam or air cushion, to reduce the impact during transportation. For products that need to be displayed, we may design transparent windows or display windows to make the products more attractive on the shelves.

We’ll also consider internal compartments to separate different product parts or accessories to ensure they don’t move around or bump into each other inside the box.

- Recommend best solution based on product size, shape, weight, fragility

- Prevents damage, enhances unboxing experience

Compartments & padding

For extra protection, we add compartments and padding to the inside of the box. These can be foam, cardboard, plastic or fabric, depending on the sensitivity of the product and the level of protection required.

We calculate the thickness and distribution of the padding to ensure stability during transportation, while avoiding over-packaging and reducing material waste.

- Separate different components or quantities

- Variety of protective liner materials

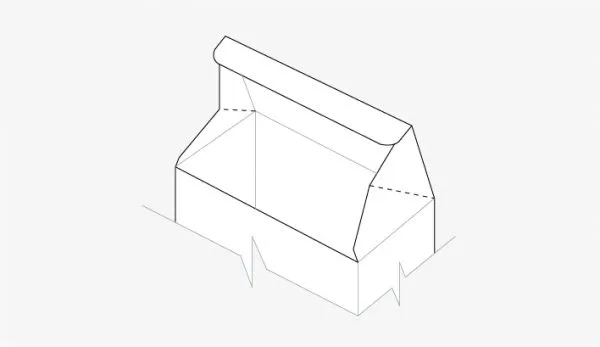

Support structures

For products that require additional support, we design sturdy support structures, such as corner braces, edge reinforcements or internal frames, to enhance the overall strength and stability of the box.

These support structures not only protect the product, but also increase the weight-bearing capacity of the box to a certain extent, ensuring safety during stacking or transportation.

- Thickness, shape, material provide load-bearing support

- Structural design techniques optimize corner, edge, surface support

Opening

The design of the opening needs to take into account the user experience and the accessibility of the product. We will provide a variety of opening options, such as full-open, half-open, magnetic closure, zipper, etc., to meet the needs of different customers.

For packages that need to be opened and closed frequently, we prioritize durable and easy-to-open mechanisms.

- Custom openings like perforated tear strips, pull-tabs, lift-off lids

- Intuitive designs for easy content access without frustration

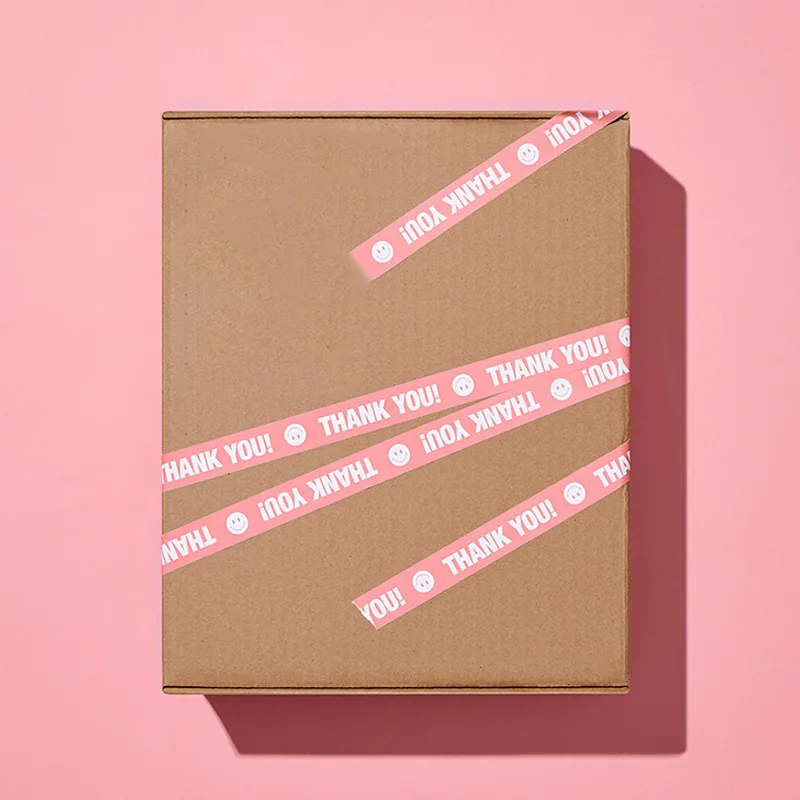

Sealing method

The sealing method is crucial to maintain product freshness and prevent contamination. We choose the right sealing material according to the product’s characteristics, such as adhesive tape, heat-sealing film, self-adhesive seals, and so on.

For products that need to be protected from moisture, dust or maintain a specific gas environment, we will also consider using special sealing techniques such as vacuum packaging or gas-conditioned packaging.

- Options from tuck-in flaps to sealed-seam carton styles

- Tamper-evidence or easy re-closure

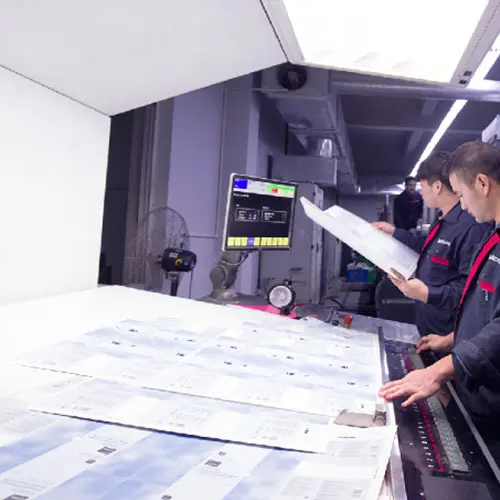

One of the top printed packaging manufacturers in China

A supplier that has been deeply involved in the printed packaging industry

In the last 20 years, we've made it happen:

- Invested over 10 million in the latest printing and packaging equipment and technologies, increasing production efficiency by 30% and reducing defects to less than 0.5%.

- Built a workforce of over 100 employees and provide internal training programs to continually advance employee skills and capabilities.

- Established partnerships with over 2000 domestic and international brands, providing packaging solutions for food & beverage, pharmaceutical, cosmetics, and other major industries.

- Developed proprietary green packaging materials, with 30% of current packaging using renewable, recyclable or biodegradable materials, significantly reducing environmental impact.

- Established in-house tooling and mold development capabilities resulting in 90% of projects having custom proprietary molds, upholding unique brand aesthetics for customers.

2000+ customers worldwide trust us

Two Decades of Excellence

Over 20 years in the industry, delivering top-notch printing and packaging solutions.

Cost-Efficiency

Reduced client expenses by 15%, offering competitive pricing without compromising quality.

Innovative Packaging Solutions

Developed 50+ cutting-edge packaging designs, catering to diverse client needs.

99.9% On-Time Delivery

Consistent track record of meeting deadlines, ensuring timely product delivery.

Consult with an Exclusive Customized Packaging Specialist

One-stop service and favorable price

From design to printing, one-stop service saves your time. Provide bulk discounts for wholesalers to reduce purchasing costs.

Excellent printing quality

Advanced printing technology ensures bright colors and clear patterns. Use environmentally friendly materials to show corporate social responsibility.

Volume discounts

We offer competitive prices and volume discounts to reduce your purchasing costs and increase profit margins.

Flexible Logistics Arrangement

We cooperate with a number of logistics companies to ensure that your goods can be delivered to their destinations safely and on time.

Get Started with GPPacking!

We always want to make sure our customers get the best price, so please let us know what you are interested in and we will provide a quote!